1 month by cncdivi

One of the best ways to learn how to make your business more successful is to study the practices of other businesses, especially successful businesses. Being aware of what other businesses do and comparing your business to them goes under a lot of names, but two you’ll hear often are Benchmarking and Best Practices.

MMSOnline’s annual Top Shops survey is a fantastic Benchmarking resource for machine shops–one of the best there is.

What makes a Top Shop?

Modern Machine Shop defines the term “Top Shop” as:

The group that represents the top 20 percent of shops as determined by totaling the points assigned to certain business- and technology-related questions.

These are the shops they feel are leading the pack in terms of their business success and technology leadership, in other words.

I’ve reported on these surveys in the past, and again last year. It’s always with an eye towards putting my own data analysis spin on the data so we can glean some insights that are not directly reported by MMSOnline. Be sure to read their survey results as well, as I’m specifically trying to come at these numbers from a different direction than they have.

It’s a big survey, so there’s room to learn some things that haven’t already been reported. This year’s Top Shops survey just came out, so I wanted to do the analysis and get it out to you in a timely manner.

What’s Different About This Analysis?

Analysis: It’s an issue with distinguishing the signal from the noise…

The real trick is in understanding which things Top Shops do differently that actually matter. It’s a signal-to-noise problem, in other words.

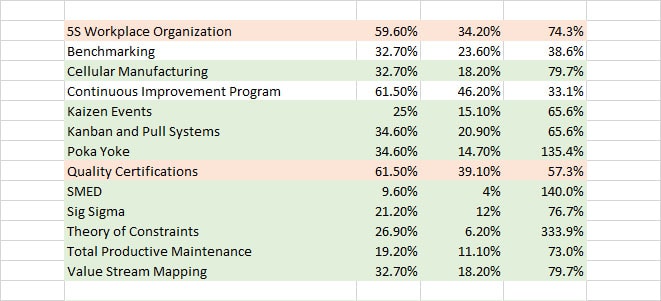

What you have to do is come up with an algorithm to separate the signal from all the noise. In this case, what I was interested in understanding is what the majority of Top Shops were doing that the majority of Other Shops don’t. So there were four criteria I used to find things worth checking into:

- If more than half the Top Shops have taken on the practice, that’s news. It suggests those things are Top Shop Best Practices.

- At the same time, the likelihood of taking on the practice had to be hugely higher for a Top Shop than an Other Shop. In other words, it had to be something fairly unique that Top Shops were doing that Other Shops were not. Last year, I drew that line at 30% more likely for a Top Shop to adopt the practice than the average. This year, I’m going to be even tougher. The difference between Top Shops adoption (or rejection) of a technology or practice and that of the rest of the shops needs to be 50% or greater.

- I also wanted to call out practices that have become so common across all shops that they can’t be ignored. These are table stakes, and if your shop doesn’t follow, you’re risking being at a considerable competitive disadvantage to almost every player, Top Shop or not.

Sounds simple, but the results were interesting and present some different conclusions than MMS gave in their write up, so let’s dig in.

Table Stakes: Pay To Play

Table Stakes: Practices so common across the industry you can’t get in the game without them…

Let’s start with what I’ll call “Table Stakes”–these are practices that are so common across all shops in the survey (more than half reported these) that you need to consider them for your own shop lest you be left at a broad competitive disadvantage in the industry.

Here’s the list of Table Stakes:

70% or Greater Adoption

Across all shops surveyed, 6 areas had 70% or Greater Adoption:

- 90.6%: Use of 3D printers to create plastic look and feel prototypes during the design stage.

- 81.5%: Vertical Machining Centers (VMC’s)

- 79.6%: CAD -3D

- 74.5%: ERP/MRP software in use

- 73.1%: Own a non-CNC milling machine

- 71.6%: Own a non-CNC lathe

Interestingly, while a majority of top shops did follow the practice, top shops were 18% less likely to have a non-CNC mill and 14% less likely to have a non-CNC lathe.

I’ve said for a long time that the average Bridgeport in the corner could be much more productively replaced by a low-end CNC such as a Tormach mill.

60% or Greater Adoption

Continuing to areas with 60% to 70% adoption we have:

- Indexers/rotary tables

- Sawing Machines

- Turning Centers, horizontal

- 3D printers for Tooling and fixturing for internal use

- Carbide recycling

- Multiple workpiece fixturing

- Customer tours

- Shop does Prototyping work

- Continuous-improvement program

- Drilling machines

- Optical comparators

- Sales personnel

- Online – company’s website

50% or Greater Adoption

Here are the items in the 50-60% adoption range:

- Through-tool coolant delivery

- Chip handling equipment

- Custom/specialty tooling

- CMM (in quality dept)

- Coolant management

- HSM

- CMM

- High-pressure coolant delivery

- Grinding machines (for workpieces)

- Desktop 3D printer for plastic parts

- Quality certifications (e.g. ISO, NADCAP, etc.)

- Just in time deliveries to customers

- On-machine probe for tool breakage/measurement

- Marking/engraving equipment

All the technologies, processes, and areas listed above are things I would not want to try to run a shop without. They’re so pervasive that being without them may lead to a serious competitive disadvantage. In other words, they’re Table Stakes if you want to run a successful machine shop.

Top Shop Best Practices

Let’s say you’re running a shop that isn’t a Top Shop. But, you’d like to improve and join their ranks.

What are the most important technologies and practices your shop should adopt to accelerate joining the ranks of the Top Shops?

I define these as “Top Shop Best Practices” because they satisfy two criteria.

First, at least half of all Top Shops follow them.

Second, they are listed in order of biggest difference between Top Shop and Other Shop adoption to least. So, for example, Top Shops are 60% more likely than the average to adopt Lights Out Machining, while Other Shops are 15% less likely. The difference between 60% and -15% is 75%, which is how I scored Lights Out Machining.

Put another way, they’re things the Top Shops agree on that Other Shops are much less likely to have hit on.

Lights Out Machining: 75% greater likelihood

Lights Out Machining: Huge Advantages But Hard to Achieve…

This is the #1 difference. 64.1% of Top Shops practice Lights Out Machining, and they’re 75% more likely than Other Shops to do so.

If you do the math, it isn’t hard to understand why, so let’s dig in a bit. The single largest cost any of these shops have is people, not machines or tooling. Lights Out lets the machines keep working after the people go home. As such, any parts or work done during Lights Out is free of people charges (almost anyway, there’s the cost to setup the job before the people went home).

That’s a huge financial advantage that’s well worth pursuing. If you’re interested in learning more, we have a couple of great articles on the topic:

4-Axis Full Contour Machining: 64%

70.3% of Top Shops can do this kind of machining while only 40.6% of Other Shops do it. I read that as a big competitive advantage that may allow Top Shops to bid on jobs the Other Shops can’t even attempt to bid on. With less competition, this may result in higher-margin business.

Job Estimating Software: 61%

Job Estimation is huge, especially for Job Shops. If you have an advantage bidding on jobs, it stands to reason you will benefit. Without software, it’s hard to ensure your bids are predictable and consistent. That makes it hard to get better at estimation over time.

In addition, without software, the labor costs associated with bidding are higher too.

Consider how being better at bidding jobs can benefit your shop:

Knowing which jobs not to bid on: Being able to quickly triage undesirable jobs so you don’t even invest the effort to bid is helpful.

Knowing how competitive you need to be: If you always shoot to be the cheapest bidder, you’re probably leaving money on the table. You need to develop an understanding over time of how competitive you have to be to win the business. If you can track that mark and ride it, you’ll maximize your profits.

Eliminating the overhead of bad bids: Losing money on jobs is a non-starter. You have to make it back over bidding other jobs. It all makes you a lot less competitive.

Knowing your business by the numbers, start to finish: If you have automated estimation with software, you are building a valuable resource over time. By comparing bid to actual numbers at fine levels of detail, you will uncover areas needing improvement and that can increase the overall profitability of your business steadily.

Let’s look at it another way. Accurately knowing what any part will cost to manufacture, and knowing that more quickly and cheaply than your competition is a huge advantage. You can use your bidding to drive higher profits or greater business volume–the choice is yours.

For more on estimating software, be sure to check out:

- Cost Estimating for Machining and Manufacturing: Our best overview guide to this area.

- G-Wizard Estimator: Our cost estimation software. Free to G-Wizard Calculator users during Beta Test.

Tool Presetting: 57%

Tool Presetter or On-Machine Tool Probe? Top Shops use both…

This is an interesting one. These days, there are two choices for setting up your tool data:

- Tool Presetting: Tool Data is picked up in the Tool Room so the machine can spend valuable cycle time making parts.

- Tool Probes and Touchsetters: Tool Data is picked up by sensors installed on the machine.

70.8% of Top Shops have Tool Probes on their machines versus 47% of Other Shops–they’re very popular. More popular than presetting, in fact. Only 58.5% of Top Shops have presetting versus 35.7% of Other Shops.

Top Shops are therefore more likely to have presetting capability, and in fact, clearly the majority of Top Shops have both.

What gives?

The answer is twofold.

First, always be cognizant of whether you want to save Cycle Time (use a presetter) or Setup Time (use a probe). For larger runs, save Cycle Time. For prototypes and short runs, save Setup Time.

Second, even thour you may use a Tool Presetter to gather the initial data, having a Tool Probe on the machine lets you automatically monitor tool wear and breakage. This is key for Lights Out Machining, but it also ups yoru game in normal runs during the day too. The more youc an automate, the greater your savings on people costs, which are the largest cost component for any shop.

CMM: 52%

CMM’s (Coordinate Measuring Machines) save time on inspection. So Top Shops have them in their quality control departments.

There’s a part of me that wonders too whether the better inspection technologies of Top Shops allow them to enter higher precision markets with less competition. Can’t tell from this survey, but it sure seems like a good hypothesis.

For more on tolerances, check out our article: The High Cost of Tight Tolerances.

Certification of Major Suppliers: 50%

55% of Top Shops certify their Major Suppliers. It would be fascinating to drill down on this and understand better what’s involved.

More Top Shop Best Practices

Through Spindle Coolant: Like a Nozzle in your tool’s tip. (Image courtesy of MC Machinery Systems)

Top Shops have a long list of best practices, to be sure. I counted 55 areas from the survey that over half the Top Shops do that they are more likely than Other Shops to do at varying levels.

Here’s the next level of Best Practices that Top Shops are 40% more likely than Other Shops to do:

- Through-tool coolant delivery

- High-pressure coolant delivery

- On-machine probe for tool breakage/measurement

- On-machine probes for workpiece measurement

- Barfeeders

- Quick-change devices

- Machine mist control

- Tombstones

- Coolant management

These are pretty straightforward decisions for workholding and machine options.

At the top of the list is Through-tool coolant and high pressure coolant. Our G-Wizard Feeds and Speeds Calculator is the only F&S Calculator I’m aware of that accounts for these when calculating feeds and speeds, and I am not surprised to learn they’re an important weapon in the arsenal of any Top Shop.

These premium coolant system are not very expensive compared to the overall cost of a CNC machine, but their advantages on cycle time can be quite large.

Probing is another area the Top Shops shine in. We ran a survey on probes last year and found extremely high adoption and customer satisfaction trends among CNCCookbook readers. They work extremely well and can save a lot of time and money. It’s no wonder the Top Shops use them so commonly.

In terms fo the rest of the items, they’re aimed at reducing Setup costs in some form or fashion. Machines with barfeeders can run longer unattended. Tombstones and Quick-change devices allow machines to be rapidly configured for a job.

Top Shop Don’t Do’s

Just as interesting as what Top Shops do is what they don’t do. What areas do they buck conventional wisdom by being radically less likely to adopt than the average shop?

Apathy is #1 thing Top Shops Avoid

A number of categories include a “None of the above” answer where shops could indicate they weren’t pursuing any of the options. THis si something Top Shops just don’t do. In fact the top 7 out of 8 things Top Shops are less likely to do than Other Shops is choose “None of the above.”

I read this as Top Shops care deeply about improving their capabilities and becoming more competitive. They’re simultaneously tackling improvement across almost eveyr dimension.

Other Areas Top Shops Avoid

- Gear Cutting Machines

- Industrial scale 3D printing of plastics

- Broaching

- Online advertising

- Having no formal process improvement methodology

- Grinding machines for cutting tools

- 3D Printers for Functional Prototypes

- Tradeshows & Event Marketing

- 3D Printing Metal

- Milling machines (non-CNC)

- Short-run initial production with 3D printers

- Full production with 3D printers

- Lathes (non-CNC)

I read this as Top Shops aren’t afraid to outsource specialty tasks like Broaching or tool sharpening. They don’t see the ROI in onilne advertising, and frankly neither do I. CNCCookbook experiments a bit with ads every year and every year I decide its a waste of money. THey also don’t believe tradeshows are worth investing in for marketing.

Forget 3D Printers

Top Shops don’t seem to buy into the 3D Printer hype…

One fascinating conclusion that MMS stopped short of mentioning is that all the data I see suggests Top Shops don’t have a lot of use for 3D Printers. After all the hype they’ve had over the years, Top Shops have largely avoided them or pigeonholed them for specific tasks like design look and feel prototypes.

Top Shop Technology Leadership

This is our last category. Here, we’re looking for outlier bets. These are areas where Top Shops have stuck their necks way out compared to Other Shops, but not the majority of Top Shops. These things haven’t entered the Top Shop Mainstream yet, but they may be the next big things to look at in the future.

Machine condition monitoriing

Machine condition monitoring is right on the cusp of becoming a Top Shop Best practice. At 39.1% adoption, it’s getting close. It is hugely more popular among Top Shops than Other Shops. The difference is 126% between the two.

Machine condition monitoring means being able to pull data of each individual machine on your shop floor about what it’s doing. Presumably, that data allows you to dramatically improve the efficiency of your shop floor.

Minimum quantity lubrication (MQL)

To an extent this one surprised me, as it is a requirement more in Europe than the US. What’s not immediately clear is whether these are Europeans weighing in as Top Shops or not. Let’s assume we’re talking US shops. Coolant can be expensive, so MQL will save on those costs.

Also, there are cases where coolant should be turned off to increase tool life. But, you’d better have good alternatives in place.

Tool balancing

I believe this reflects the trend towards HSM and faster spindle speeds. Balancing tools will improve your tool life at most rpm ranges, but it’s critical as you start to spin at 10,000 rpm and up.

Ballbar calibration

Regularly calibrating your CNC machines assures their peak performance. It’s not all that difficult or expensive to do, but the Top Shops have the lead on getting it done.

Single-minute exchange of dies (SMED)

This is all about how quickly you can get set up for an entirely new job. Palette changers, modular fixture plates, and similar technologies all help.

5-Axis (positioning only)

Another interesting one to see coming into play. 43.8% of Top Shops are using this technology.

Flexible manufacturing systems

These are HMC’s equipped to automate loading of tombstones and parts. Typically they have big magazines of tooling as well. They’re the peak of automation for milling.

YouTube

I’m fascinated to see Top Shops embracing YouTube for marketing purposes. 23.1% do it, so far from the majority, but Top Shops are 69% more likely to be on YouTube than Other Shops.

Here’s a great example of a Formula One Bolt:

Conclusion

There you have it: Top Shops data sliced an entirely different way. Hopefully, we’ve made it easier for you to see some patterns that will help your shop grow faster and become even more competitive.

If you’d like to get your hands on my analysis spreadsheet to do your own slicing and dicing on the data, no problem. I’m making it available to anyone who subscribes to our newsletter:

Like what you read on CNCCookbook?

Join 100,000+ CNC'ers! Get our latest blog posts delivered straight to your email inbox once a week for free. Plus, we’ll give you access to some great CNC reference materials including:

- Our Big List of over 200 CNC Tips and Techniques

- Our Free GCode Programming Basics Course

- And more!

Just enter your name and email address below:

100% Privacy: We will never Spam you!

Bob is responsible for the development and implementation of the popular G-Wizard CNC Software. Bob is also the founder of CNCCookbook, the largest CNC-related blog on the Internet.

![The Most Loved CNC Controls in 2017 [Survey Results] Gcc conducts a survey to determine customer satisfaction using their CNC Controls in 2017, revealing the most loved results.](https://www.cnccookbook.com/wp-content/uploads/2017/10/img_59d3d01a41a4e.png)

![CNCCookbook 2017 CAD Survey Results [+Customer Satisfaction Awards] Ciscobook 2017 overall CAD Survey Results.](https://www.cnccookbook.com/wp-content/uploads/2018/03/img_5a9f0cee60280.png)