SOFTWARE

Articles relating to all the many kinds of CNC Software. Complete Guide to CNC Software [ 21 Types of Digital Tooling ]

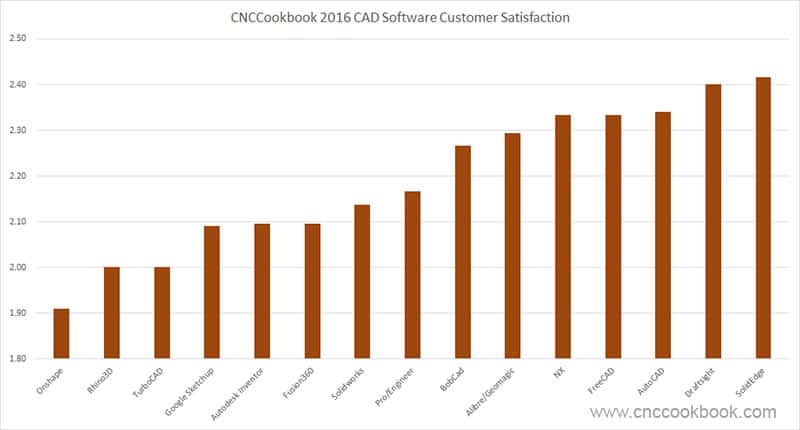

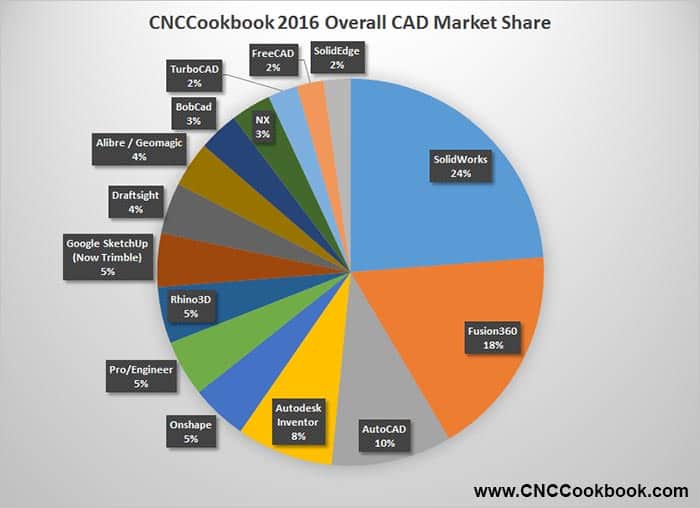

CNCCookbook 2016 CAD Survey Results, Part 1: Market Share

We’ve just hit a critical mass of hundreds of responses to our 2016 CAD Survey, so it’s time to find out how everyone voted. We’ve done CAD Surveys in 2013 and 2015, so we’ll be able to see a little market trending here too. As with our CAM...

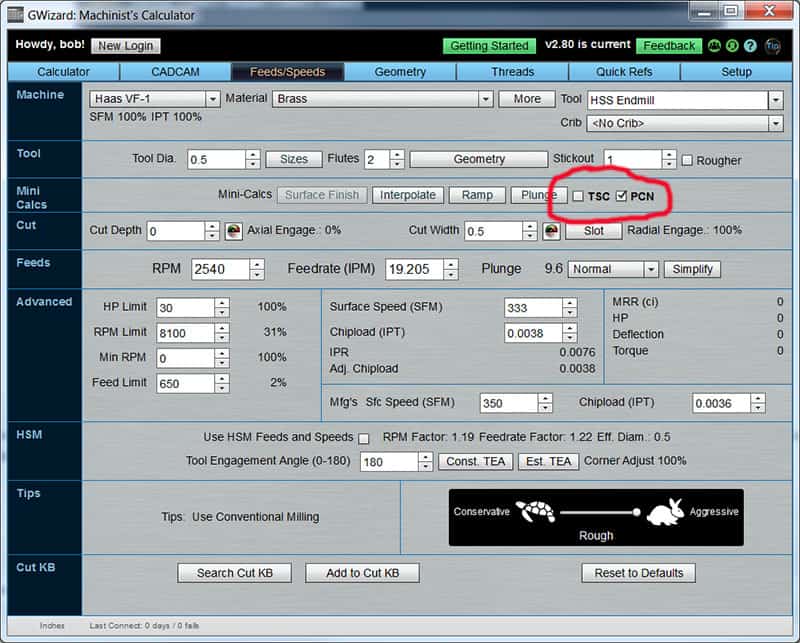

New Sharing Features in G-Wizard Products

Time for another update. I have uploaded new versions of G-Wizard Calculator, G-Wizard Editor, and G-Wizard Estimator. You can find the download links on our Help Page. There is much new in these releases. For starters all G-Wizard products can share...

Strengths and Weaknesses of the 16 Leading CAM Software Packages

Picking the wrong CAM package can be a nightmare… What sorts of things would you like to know before purchasing CAM Software? CAM is often expensive, you’ll invest hours learning to use it properly, and it may make the difference between...

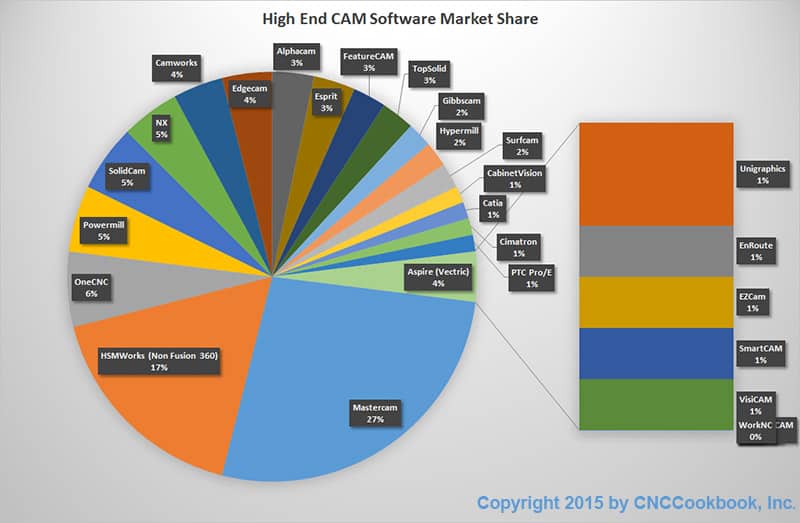

Think You Know Which CAM Packages Are Most Popular? Time to Find Out!

We are excited to announce the completion of our 4th CAM Software Market Share Survey with interesting findings. These CAM Software surveys have been conducted in 2010, 2012, 2014, and the latest in 2015. Considering the rapid changes in the market, we’ve...

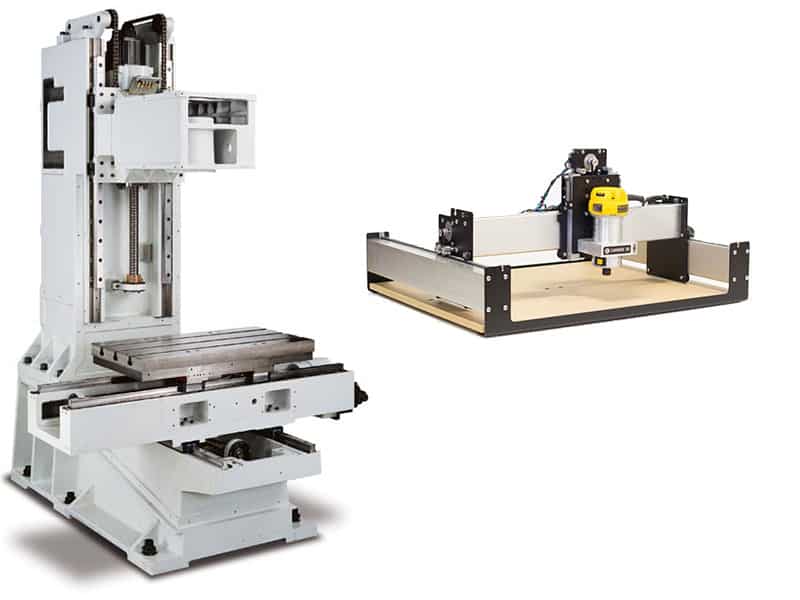

Little-Known Factors That Make G-Wizard Great for Both Big and Small CNC Machines

Is G-Wizard best for Big or Small CNC Machines? Does G-Wizard Calculator produce better feeds and speeds for big industrial machines or small hobby machines? The truth is that it has special features for both crowds. I was recently contacted by a G-Wizard user who...

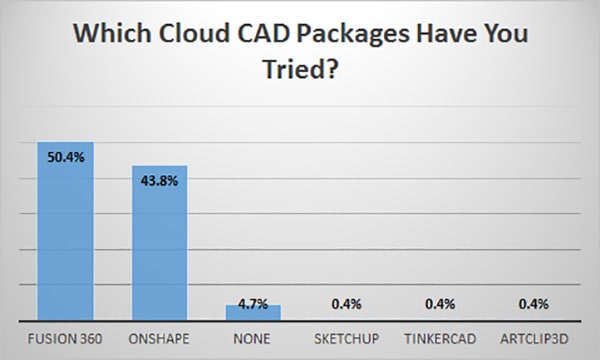

Surprising Things We Learned About Cloud CAD Software (Survey Results)

Looking for more up-to-date data? Take a look at our 2017 CAD Software Survey Results. We just finished our big survey on Cloud CAD Software, and the results are fascinating. One thing before we start. The survey was worded to encourage responses only from...

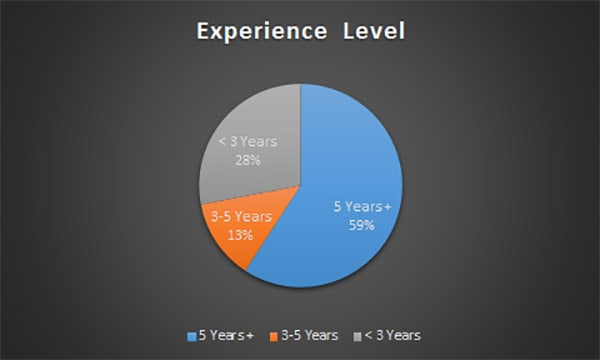

Results of our 2015 Feeds and Speeds Survey

If you’ve been wondering how your peers approach Feeds and Speeds for their CNC work, wonder no longer. Our survey was very popular and we got well over 100 responses. Who Responded? First, a little background about the respondees. On the whole, they...

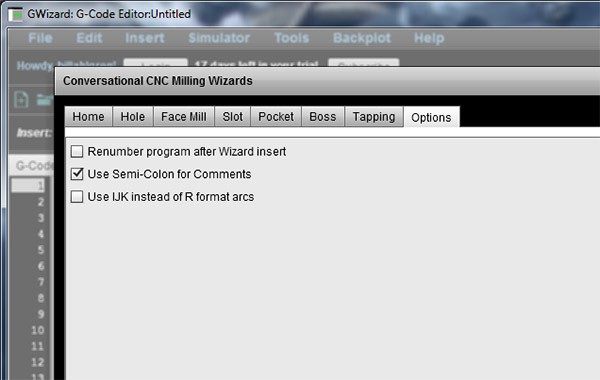

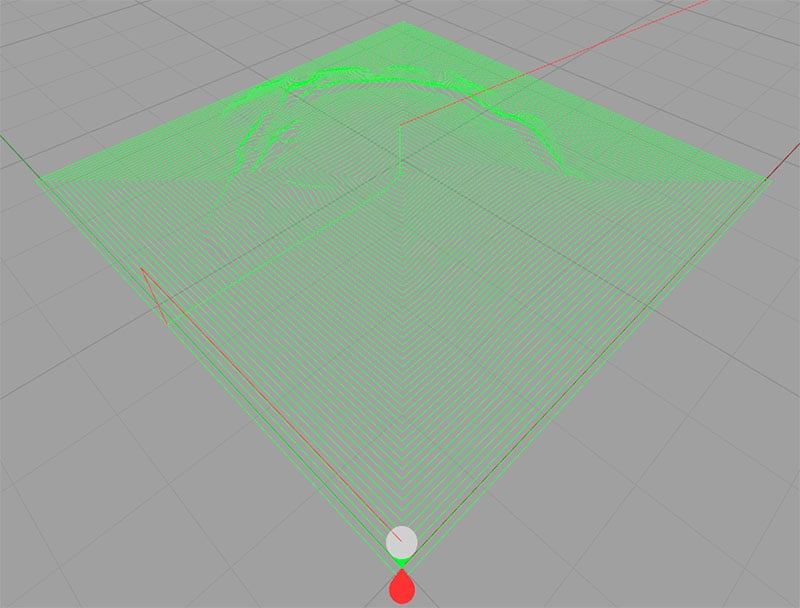

G-Wizard Editor: New Conversational CNC Features

I recently uploaded G-Wizard Editor version 2.30 on the GWE Download Page. Release 2.30 is focused on improving the existing Conversational CNC Wizards. Wondering what “Conversational CNC Wizards” are? I’m so glad you asked! Conversational CNC is...

What Everybody Ought to Know About CNCCookbook’s Upgrade, Internet, and Subscription Policies

We try to do as much as we can to help customers and simplify our software. CNC is already too complex, and we try to make it simpler. That’s hard to do if we can’t constantly be making our software simpler and more usable. So, there’s a set of basic...

Decimal Points: A Quick Way for the Unwary to Crash a CNC Machine

For those of you recently introduced to CNC, you may have noticed that more seasoned users often include a decimal point in their GCode, even when there are no digits following the dot. For instance, to move 5 inches (or millimeters if using metrics) to the right of...