by Bob Warfield | Blog, CNC Basics, GCode, Software, Tools and Techniques

Are you still using a Text Editor to edit g-code? Aw, c’mon. There’s better tools for the job. Or maybe you just don’t ever want to touch g-code with a 10 foot pole. Part of that is because you don’t have the right tools to work on g-code. ...

Details

![CNC Memory Full? [ Easy Fix: Make Your G-Code Smaller ]](https://www.cnccookbook.com/wp-content/uploads/2020/06/img_5ee14e2629a49-564x675.png)

by Bob Warfield | Blog, GCode, Software, Tools and Techniques

Ran out of CNC Memory? Living in a world where the average phone has memory measured in gigabytes it’s easy to forget that a lot of very capable CNC machines have far less memory available for gcode–especially older machines. A real old Fanuc might have...

Details

![Make A CNC Chair: CNC Furniture Plans [ Paw Chair ]](https://www.cnccookbook.com/wp-content/uploads/2020/06/img_5edbde7456c2e.png)

by Bob Warfield | Blog, CNC Basics, CNC Projects, CNC Router

My CNC Chair and CNC Furniture Project Ever had the urge to build a CNC Chair (or other CNC Furniture), but needed some CNC Furniture Plans to help you get going? In this article, I want to show you how I went about designing my own CNC Chair by creating a set of CNC...

Details

![Increase Tool Life, Reduce Tool Wear [ Easy Guide ]](https://www.cnccookbook.com/wp-content/uploads/2013/11/ToolLife.jpg)

by Bob Warfield | Blog, Feeds and Speeds, Tools and Techniques

Increase Tool Life, Reduce Tool Wear [ Easy Guide ] This guide will show you 11 ways to radically increase your tool life and reduce tool wear. For details and mechanisms of tool wear, discussion of how to calculate tool wear, and descriptions of tool life monitoring,...

Details

![Large Part Machining: 14 Tips [ Without a Big Machine ]](https://www.cnccookbook.com/wp-content/uploads/2017/02/RouterPrepCNCMill-700x675.jpg)

by Bob Warfield | Blog, CNC Basics, CNC Router, Tools and Techniques

Large Part Machining can be daunting, but it can also be a real competitive advantage. If you have the only shop in your area capable of handling bigger parts, you’ve got a leg up on the competitive. It’s not always practical to have a machine...

Details

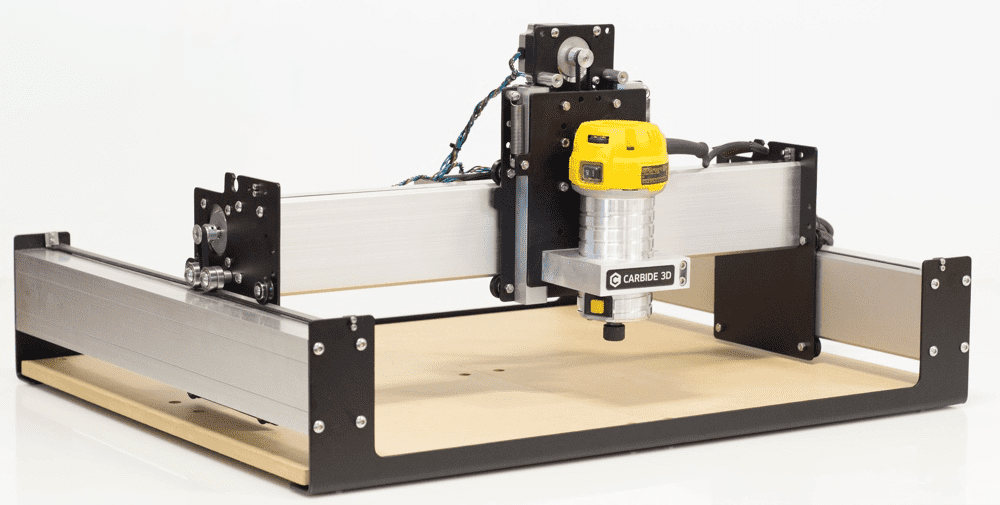

![Complete CNC Router Parts [DIY Guide]](https://www.cnccookbook.com/wp-content/uploads/2020/05/img_5ecc03298dd23-1080x675.png)

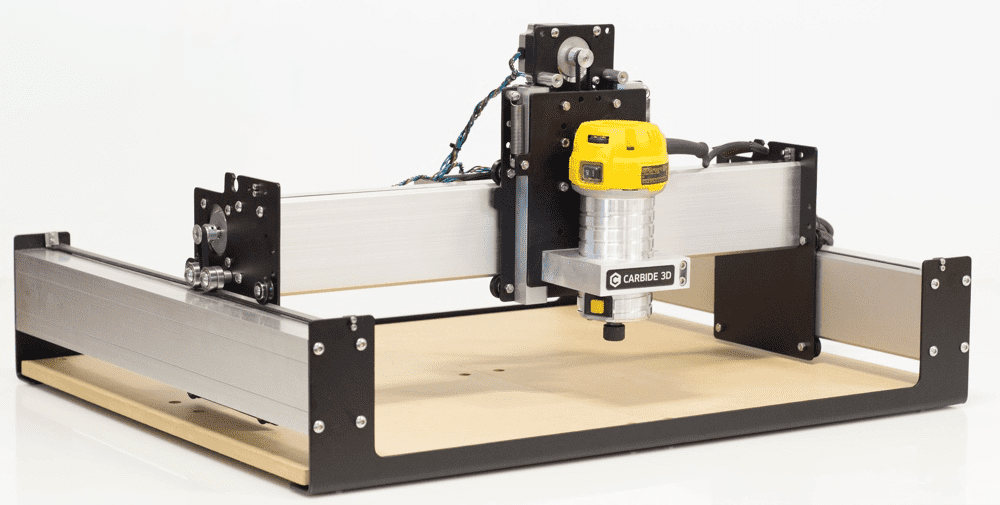

by Bob Warfield | Blog, CNC Basics, CNC Projects, CNC Router

Complete CNC Router Parts [DIY Guide] Select a Part: Frame Table Spindle Ways Drive CNC Controller Accessories This Guide to DIY CNC Router Parts is designed for exploration and learning. This page is the home page and visual table of contents. Click the menu above...

Details

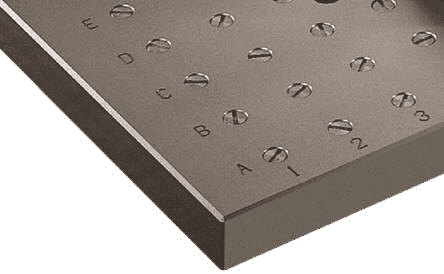

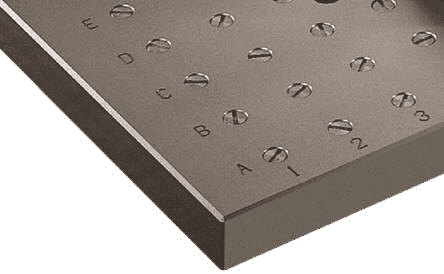

by Bob Warfield | Blog, CNC Basics, CNC Manufacturing & Job Shops, CNC Projects, Tools and Techniques

Complete Guide to Fixture Plates, Tooling Plates, and Modular Fixtures A Fixture Plate (also called Tooling Plates and Modular Fixtures) can save you a tremendous amount of time and work when setting up a CNC Machine. This Complete Guide walks you through what they...

Details

by Bob Warfield | Blog, CNC Projects

Need Some Model Steam Engine Plans? Here’s one from my archives. It’s not finished, but wouldn’t take much to finish it up and start machining. This project was inspired by the Engineman’s (John Bentley’s) gorgeous naval brass...

Details

![DIY Disk Sander [ Helpful Shopmade Tooling ]](https://www.cnccookbook.com/wp-content/uploads/2021/05/OriginalPalmgren.jpg)

by Bob Warfield | Blog, CNC Basics, CNC Projects, DIY CNC, Tools and Techniques

Note: This is a project I did many years ago as a manual machinist. It turned out great and I still use it to this day. I learned some clever tricks on this one, so it’s worth going through the whole project just to see if there’s...

Details

by Bob Warfield | Blog, CNC Router, Tools and Techniques

This year, we got not quite 300 responses, and we got them in less than a week. The last time we did a CNC Router Survey was 2017, and we got about half as many responses after 2 weeks. Thanks to everyone that contributed by taking the survey! Let’s dig into...

Details

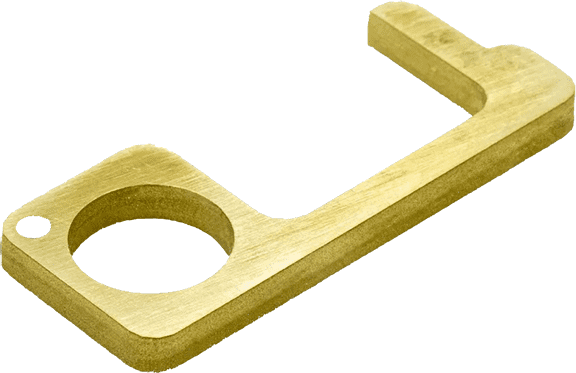

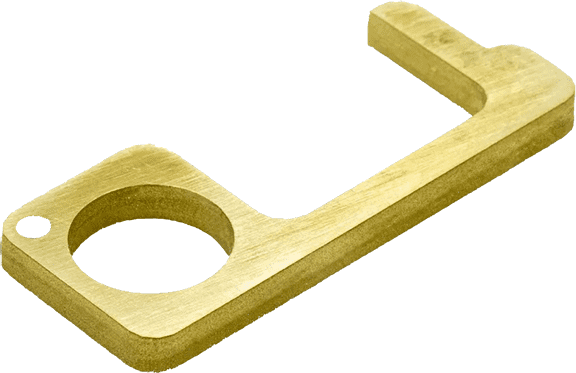

by Bob Warfield | Blog, CNC Projects

Good weather is here, at least where I live. It’s great to be outside, and many of us have time on our hands given the Covid-19 social isolation. Why not spending that time on a CNC Project aimed at Outdoor Fun? Here are some ideas for you. Sturdy...

Details

by Bob Warfield | Blog, CNC Basics, CNC Manufacturing & Job Shops, Tools and Techniques

If you’re at home, you may not need Covid 19 Best Practices, although practicing some of them in the home may increase your safety margin. If your shop is doing Essential Work, you’re going in and working. Your shop needs Covid 19 Best Practices to...

Details

![CNC Memory Full? [ Easy Fix: Make Your G-Code Smaller ]](https://www.cnccookbook.com/wp-content/uploads/2020/06/img_5ee14e2629a49-564x675.png)

![Make A CNC Chair: CNC Furniture Plans [ Paw Chair ]](https://www.cnccookbook.com/wp-content/uploads/2020/06/img_5edbde7456c2e.png)

![Increase Tool Life, Reduce Tool Wear [ Easy Guide ]](https://www.cnccookbook.com/wp-content/uploads/2013/11/ToolLife.jpg)

![Large Part Machining: 14 Tips [ Without a Big Machine ]](https://www.cnccookbook.com/wp-content/uploads/2017/02/RouterPrepCNCMill-700x675.jpg)

![Complete CNC Router Parts [DIY Guide]](https://www.cnccookbook.com/wp-content/uploads/2020/05/img_5ecc03298dd23-1080x675.png)

![DIY Disk Sander [ Helpful Shopmade Tooling ]](https://www.cnccookbook.com/wp-content/uploads/2021/05/OriginalPalmgren.jpg)