2 months by cncdivi

Note: Chip Thinning & Rubbing is Lesson 3 of our Feeds and Speeds Master Class. Sign up by clicking the link.

Chip Thinning and Rubbing: two reasons why slowing down may not lead to longer tool life.

A lot of Beginning CNC’ers back way off recommended feeds and speeds in the interest of conservatism. They think that this will reduce the risk of breaking tools. After all, how could it not?

But what if going to slowly or taking too light a cut turned out to be the worst possible thing for your Tool Life?

It turns out to be true due to two phenomena called Chip Thinning and Rubbing. Let’s learn what they are and how to deal with them so they can’t hurt our tools.

Rubbing: When You’re Feeding too Slowly

Most newcomers to machining are shocked to learn they can ruin a tool quickly by feeding it too slowly. Somewhere along the way you may have heard that feeding too slowly causes “rubbing” which is what destroys the tool.

How does that work and just what is this “rubbing” thing?

Consider a magnified view of your cutting edge versus the material:

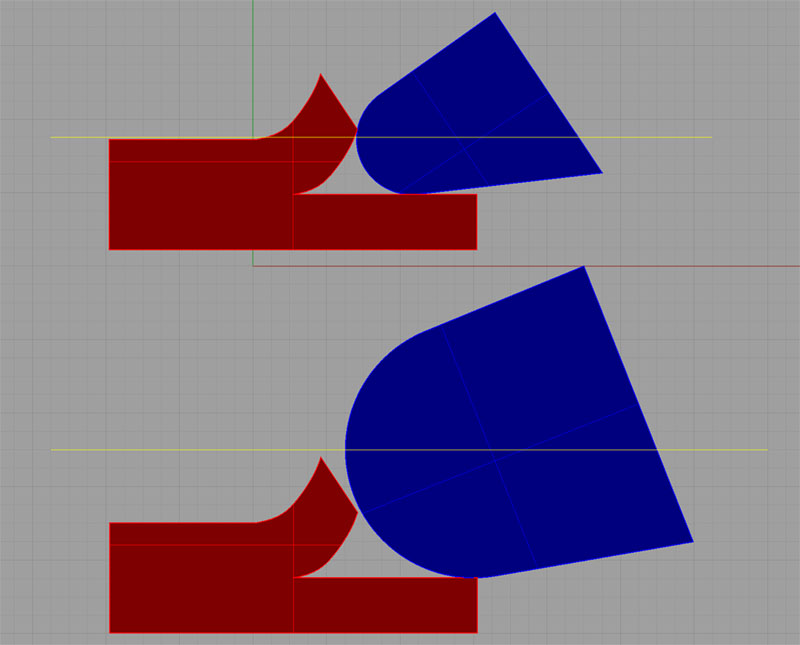

Two chip loads: Top one has chip thickness > tool edge radius. Bottom one has chip thickness < tool edge radius and will rub…

In the diagram, the cutter edge radius centerline travels along the yellow lines.

If the radius is too large relative to the depth of cut (bottom), all the force goes to pushing the chip under the edge. This is the “rubbing” effect you’ll hear talked about when feed rate and hence chip load are too low. With the force pushing the chip down instead of pulling it up, the edge rubs along the top of the cut. What the rubbing does is generate a lot of heat which is what kills tool life.

Tool manufacturers will tell you that too little feed is just as bad for tool life as too much feed (or too much spindle rpm). But how little is too little? That part is seemingly hard to find out. I went fishing around with Google to try to find what speeds and feeds result in a “burnishing” effect with tools. Here is what I found:

– Article on hard milling: 0.0008″ per tooth is definitely burnishing because it is “less than the edge hone typically applied to the insert.”

– De-Classified 1961 Batelle Institute report on aerospace machining of super-alloys says an IPR less than 0.0035 will result in burnishing and likely work hardening of these alloys. Interesting how well this number agrees with the one above for a 4 flute cutter. 8 tenths times four would be 32 tenths.

– Another reference, like the first, to keeping chip loads higher than tool edge radius. In this case, IPT should be greater than 0.001″. This is once again an article on hard machining where work hardening may be a factor.

– Minimum chip thickness is 5-20% of the cutting edge radius. Below that level, chips will not form and the cutter will “plow” across the workpiece causing plastic deformation and considerable heat.

– Ingersoll says that as a general rule carbide chip loads should not be less than 0.004″ or you run the risk of rubbing which reduces tool life and causes chatter.

– Chip Formation and Minimum Chip Thickness in Micromilling uses a figure of 20 micrometers for edge radius on micromills, which is about 0.00079″. They go on to show that the rake angle becomes extremely negative as the chip load falls below the edge radius and conclude that there is a minimum chip load below which the cutter will not cut. It varies from about 0.2 to 0.35 times the radius for various kinds of steel.

– The Rutgers research paper, “Micromilling Process Planning and Modelling for Mold Making” uses a figure of 1 to 5 micrometers for micromill edge radius, which is 0.000039″ to 0.0002″.

I take away two things:

1. If you cut too little, you run the risk of work hardening if your material is susceptible to it. That will wreck your tool life if you are over-stimulating work hardening. Imagine tossing a handful of hardened chips into the path of our cutter–that can’t be good!

2. Aside from work hardening, if you’re cutting much less than the cutting edge radius, you’re rubbing and not making clean chips. That will heat the tool and material and drastically reduce tool life.

Figuring out the work hardening part is easy. If your material is susceptible, keep the chip load up at manufacturer’s recommendations and don’t fool around.

Figuring out the whole cutting radius issue is harder. Most of the time we don’t know what the cutting radius is. I’m not talking about tip radius on a lathe tool, for example. I’m talking about the actual radius of the sharp edge. In other words, the smaller the radius, the sharper the tool. A lot of carbide inserts are pretty blunt. A chip load of less than 0.001″ may very well be too little.

Modern tools for aluminum are often much sharper, and can take less chip load. In general, indexable tools are less sharp than endmills, so they need higher chip loads.

It’s ironic that just when you think you are taking it easy on a cutter with a very light cut, you may be doing the most damage of all due to rubbing.

Why chance it though?

Use a calculator like G-Wizard to figure out how to deliver the manufacturer’s recommended chip load by increasing the cnc feed rates. Not only will the job go faster but your tooling will last longer.

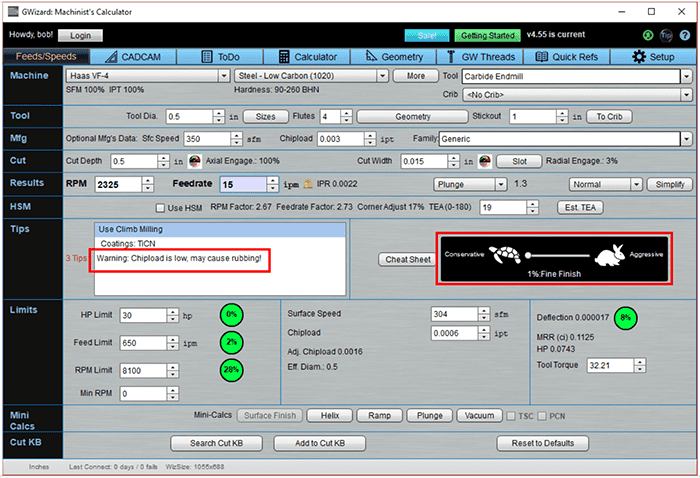

In cases where you need to reduce the chip load to improve surface finish, G-Wizard also includes a built-in rubbing warning to keep you out of trouble:

I want you to notice the two areas I’ve flagged with a red rectangle outline.

On the right, you see G-Wizard’s “Tortoise-Hare” slider. It moves cuts from most conservative (full tortoise) to most aggressive (full hare). The most conservative position is calibrated to be the slowest you can feed without rubbing. It’s handy, both to know where the limit is, but also to get the nicest possible finish. We’ll talk more about the Tortoise Hare and Finishing vs Roughing Feeds & Speeds soon, but I wanted to get that out there.

Now I manually reduced the feedrate further after setting it to the Fine Finish position, so now we are rubbing. And you can see the lefthand red rectangle shows a warning message that these settings may cause rubbing. If you use a tool like G-Wizard, you won’t have to worry about rubbing much because the software is looking out for you.

Here’s a video I made for Cutting Tool Engineering magazine on the whole topic of rubbing:

Radial Chip Thinning (aka I’m an Expert and I ran the Machine too slowly without even knowing it)

Would you believe that especially for light cuts, the basic feeds and speeds formulas combined with SFM and chip load tables often gives results that are wrong and radically increase the wear on your tools?

The reason is that there is more going on here than meets the eye due to a phenomenon called “Chip Thinning“, or more accurately, “Radial Chip Thinning“.

For example, if I poke around various endmill manufacturer’s literature in search of speeds and feeds for steel, I can get to a page like this one from Niagara cutter.

First thing to note is that the recommended chip loads and SFM vary depending on the exact operation being performed, and in particular, the depths of cuts. If you’re just using the basic shop math around SFM and chip load, no such compensation is available.

I have built compensation like this into my G-Wizard Machinist’s Calculator, but trust me, it isn’t so easy just to do it by hand. You’ll be constantly referring to pages and tables, or to Excel spreadsheets.

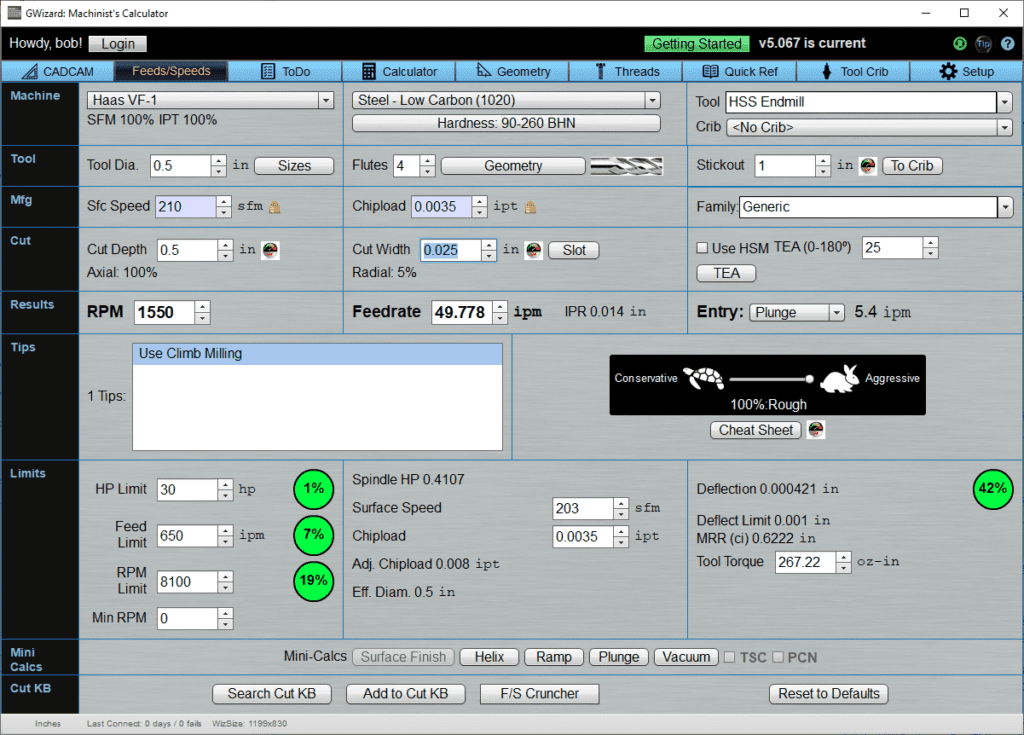

Let’s try an example based on doing some peripheral (edge) milling to profile a part made out of mild steel using a 1/2″ uncoated HSS 4 flute endmill. We plan to take fairly shallow finishing quality cuts of 5% of the cutter diameter. Further, let’s do a pretty deep cut axially, a full cutter diameter of 1/2″. So if I am profiling a 1″ high part, I can make a full pass by going around twice and cutting 1/2″ each time.

What feeds and speeds should we use?

The Niagara page says for cuts less than 1/16 of a diameter (5% is 1/20), we want 210 SFM and a chip load of 0.0035. If I plug all that into a calculator and use the standard formulas taught in most shop classes (which ignore chip thinning), I get the following results:

- Radial Depth Ratio of 5% = 0.025″ depth of cut

- 210 SFM and 0.0035 chip load gives us 22.46 IPM feed rate and a 1600 rpm spindle speed.

Is that the right speeds and feeds?

Yes and no. It’s certainly what the majority of folks would use. In fact, they might even be less aggressive than that if they’re trying to be conservative.

Let’s see what G-Wizard would suggest by default and why:

- For the same depth of cut and cutter, G-Wizard wants a little slower SFM of 203, and the same chip load at 0.0035.

- The spindle speed works out to be 1550 rpm due to the lower SFM, but the feed rate is now 49.778 IPM.

That feedrate is over 2x the conventional values.

How can we go so fast?!?? The answer is something called “Chip Thinning”, which is a geometric effect. Unfortunately, avoiding the rubbing problem gets harder, even for experts, because of “Chip Thinning.”

What is Chip Thinning?

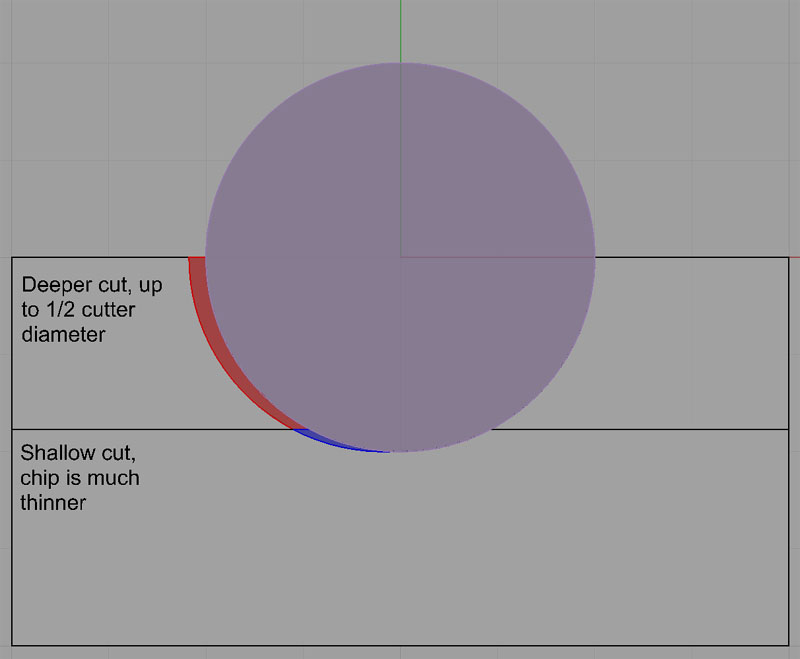

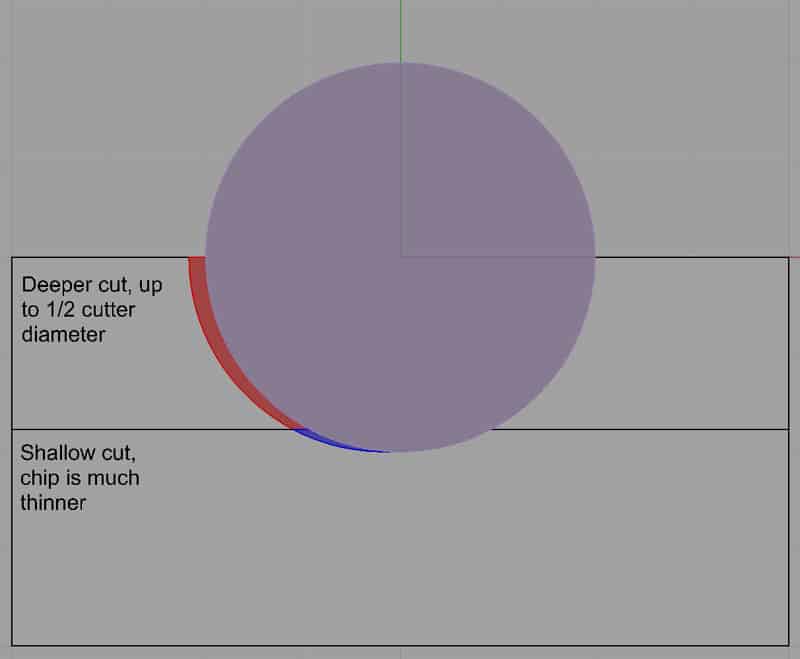

With chip thinning, you can be making a cut and following all the recommended chip loads, and still be rubbing. The cut above, 1600 rpm at 22.46 IPM will almost certainly wind up rubbing. The reason is that due to the geometry, when your radial engagement, the cut width looking down the axis of the tool, is less than half the diameter, the chips that come off are actually thinner than the basic formulas everyone learns in machinist’s school predict. A picture is worth a thousand words when understanding why:

The blue chip is a shallower cut. Note how thin it is at its widest compared to the red chip from a deeper cut…

The blue chip represents a very shallow cut, and the red chip a deeper cut. Note how thin the blue chip is at its widest compared to the red chip from a deeper cut.

You can see that the chip gets thicker all the way up to the point where we’ve buried the cutter to 1/2 its diameter. That’s the thickest point.

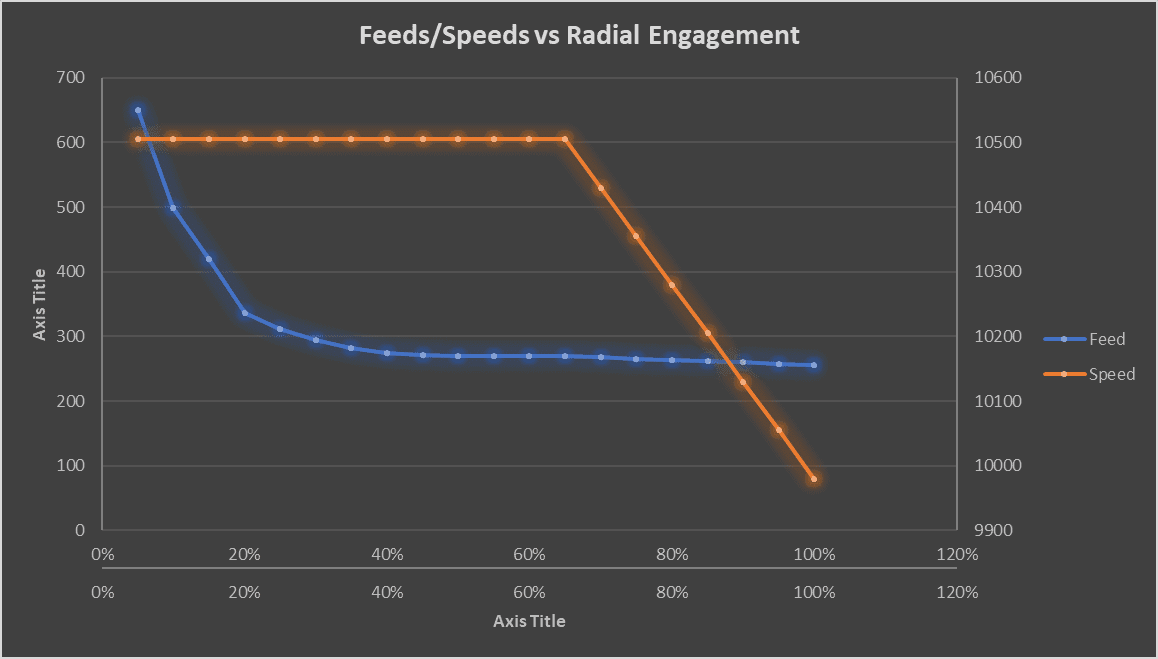

Chip thinning calculations answer the question, “How much faster do we have to go so the maximum width of the blue chip is the recommended chip load?” This graph gives an idea of just how strong an influence chip thinning has over feedrate:

Effect of Chip Thinning on Feedrate…

The Blue Line is feedrate while the axis at the bottom is Cut Width. Note the almost exponential effect chip thinning has on feedrate as we move to lower and lower Cut Widths!

Because we’re just trying to get back to the recommended chip load, chip thinning isn’t about going faster in the sense of higher MRR’s. You will see your machine going faster, sometimes a LOT faster, but chip thinning is about avoiding rubbing that will dramatically shorten your tool life.

Many manufacturers publish tables that suggest how much faster to feed based on the % of cutter diameter you are cutting. A good machinist’s calculator, like G-Wizard, will factor in chip thinning automatically.

Unless you always cut more than 1/2 the diameter of your tool, you need to make sure you’re adjusting your cuts for chip thinning or you’re probably wearing out tools prematurely as well as not taking full advantage of the material removal rates the tool is capable of. Here’s a video from my “CNC Chef” column over on CTEMag that goes over Chip Thinning:

Chip Thinning Calculator

Would you like a Chip Thinning Calculator? Heck yeah–we’ve already shown how much Chip Thinning can affect your Feeds and Speeds.

You have 2 choices:

#1 – Get a free trial of G-Wizard Calculator. It automatically factors in chip thinning for everything it does, not to mention a whole bunch of other awesome stuff.

G-Wizard Calculator Free Trial

#2 – Download our free Chip Thinning Calculator. It’s an Excel spreadsheet that will perform chip thinning calculations. Plus, we’ll sign you up for our free Newsletter.

It’s your choice, but given the G-Wizard trial is free and it does much more than just Chip Thinning, that’s where I’d start!

There’s More than One Kind of Chip Thinning

We’ve been talking about what is properly called “Radial Chip Thinning”, but there’s more than one kind out there. You can get chip thinning any time a circular cross section is presented to the cut from any angle. For example, say you’re using a Button Cutter, which is an indexable cutter that uses round inserts. Yup, it has a type of chip thinning. Or suppose you’re using a ballnosed end mill. You guessed it–more chip thinning.

Accounting for Chip Thinning in multiple dimensions becomes harder and harder. That’s why I leave it to dedicated software like our G-Wizard Calculator.

Like what you read on CNCCookbook?

Join 100,000+ CNC'ers! Get our latest blog posts delivered straight to your email inbox once a week for free. Plus, we’ll give you access to some great CNC reference materials including:

- Our Big List of over 200 CNC Tips and Techniques

- Our Free GCode Programming Basics Course

- And more!

Just enter your name and email address below:

100% Privacy: We will never Spam you!

Recently updated on March 6th, 2024 at 03:06 pm

Bob is responsible for the development and implementation of the popular G-Wizard CNC Software. Bob is also the founder of CNCCookbook, the largest CNC-related blog on the Internet.

![Tap Speed and Feed Calculator [Free + Pro Calculator] Tap Feeds and Speeds Calculator Tapping Drill Chart](https://www.cnccookbook.com/wp-content/uploads/2016/07/TappingDrillChart.jpg)

![NPT Thread Calculator / Pipe Thread Calculator [ Free ] Screenshot of the g-wizard pipe thread calculator software displaying thread specifications and a graph showing drill sizes and clearances.](https://www.cnccookbook.com/wp-content/uploads/2024/04/img_66180ecd75fa8-150x150.png)

![Press Fit Calculator and Tolerances [ Free Software ] A computer screen displaying the settings for a wireless network with a press fit calculator.](https://www.cnccookbook.com/wp-content/uploads/2018/10/img_5bd6355a7d790.png)