2 weeks by cncdivi

Receiving personalized advice, guidance, and mentorship is invaluable. Having a hotel concierge guide you to the best restaurant that suits your taste in a foreign city can certainly turn a meal into a treasured memory. Similarly, having a close friend who is an expert in CNC due to their lifelong career in that field can truly expedite your learning process and sometimes becomes pivotal when dealing with challenging issues.

These days, we turn increasingly to the Internet for this kind of information. But it can take quite a lot of searching to find what you need, especially if its something you either don’t understand well enough to choose the right words to search for in Google, or worse, if it’s something you didn’t even know you needed to know. Pretty tough to search for that last one!

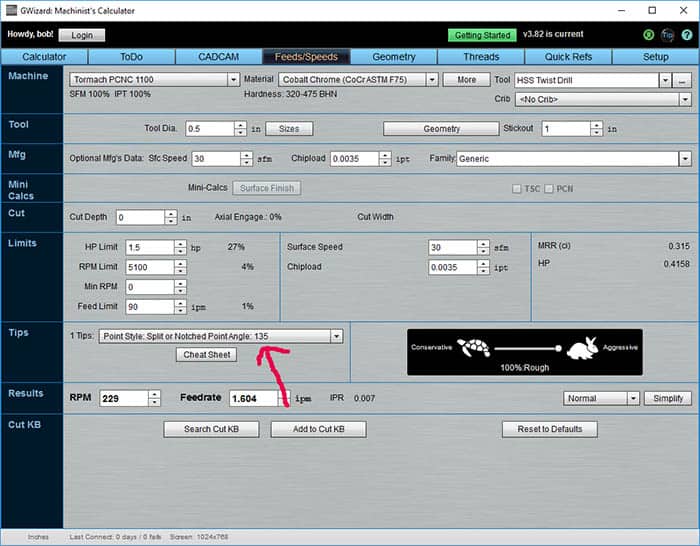

For example, let’s talk about twist drill point angles for a minute. Many beginners don’t realize there are different point angles that are more optimal depending on what the material is. Aluminum is fine with the standard 118 degree angle. You can use 118 in cast iron, but it also likes 135. If you’re working with some nasty tough Cobalt-Chrome alloy, perhaps for a medical device, it wants a split point with a 135 degree angle.

Now even if you knew about point angles, how top of mind are they? Do you go running for your Machinery’s Handbook to try to find the right angle every time you get a job with a new material? Probably not.

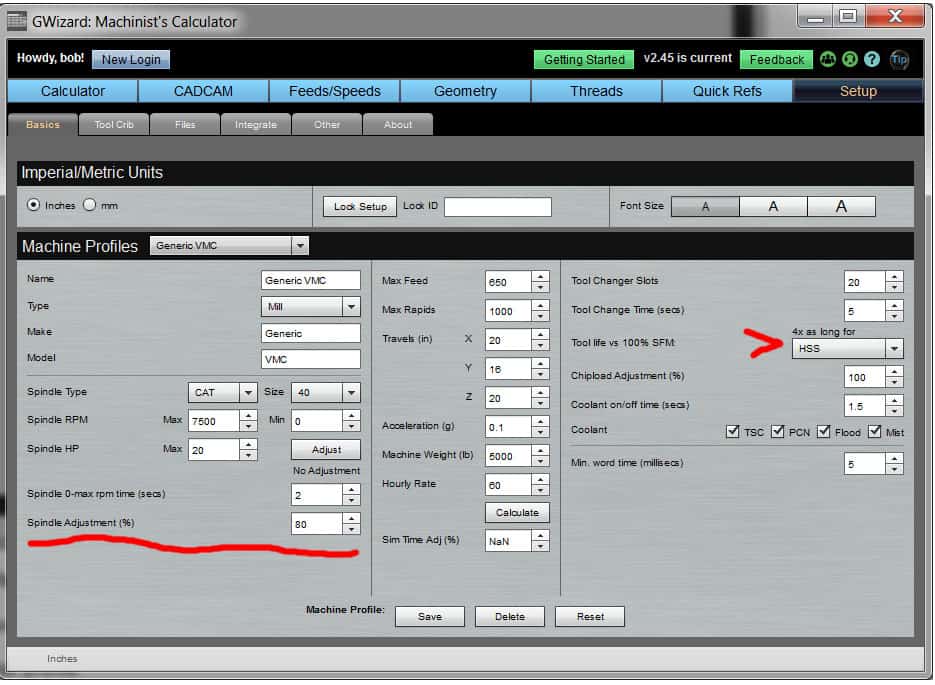

But, our G-Wizard Calculator has a feature called “Tips” that keeps up with this sort of thing for you. Here’s that Cobalt-Chrome twist drill tip, for example:

Twist Drill Point Angle Tip…

There are a lot more tips too. Just for Twist Drills, the tips cover the following:

- Point Angle

- When your hole is deep enough you’ll need a Parabolic Flute drill

- Peck depth for peck drilling

- Hole is too deep. Sometimes you just can’t fix it with slower feeds and speeds.

- When to drill a pilot hole

- Proper drill size for a reamer

In fact, G-Wizard has hundreds of these tips built in, and they’re all triggered by the information you input in the process of calculating your Feeds and Speeds.

There are tips that are cutter specific, material specific, and exact combination of conditions specific. For example, most CNC’ers will always Climb Mill. But there are certain combinations that will work better for you if you Conventional Mill when they come about. G-Wizard will let you know when that happens.

Tooling Catalogs: Not much plot, but the characters are fascinating!

Let me tell you the story of how Tips came to be. Many years ago, when I was first creating the software, I would pore over the technical information in tooling catalogs. I have a collection of about 200 of these catalogs, and I was always fascinated by all the hints and tips they contain. I had long lists of notes capturing those tips in hopes I could learn and apply them to my own work.

At first, I would simply try to remember these things as I went about my work. No chance–there were hundreds of them. With a lifetime you might learn a lot of them, but I’ll bet there are very very few machinists who know and use all of them.

Then I tried to create a sort of checklist based on the operation being performed. That was still painfully unworkable. I needed a way to organize the tips that was completely painless and automatic.

The light bulb lit…

Suddenly the light bulb lit–G-Wizard was getting all the right information to know which tips to recommend. I had always thought of it literally as a calculator that only provided numbers, but it could also give advice too. Best of all, you were going to enter the information anyway to calculate Feeds and Speeds, so the tips were a completely free luxury–no additional work required to take advantage of them.

I haven’t written about the Tips feature very often. In fact, I couldn’t find even one article totally dedicated to Tips. That’s my bad, but I think they’re one of the real unsung heroes in G-Wizard because they’re so handy and also so easy to take advantage of. And I’ve never seen them in another Feeds and Speeds product. Go figure.

Over time, I have kept adding more and more tips. There are even special DFM (Design for Manufacturing) tips over in CADCAM Wizards that can help you understand how to reduce the cost to manufacture parts. And yes, I still read through every tooling catalog I can get my hands on as well as many many other article sources. It’s the only way to bring you the latest and greatest information via G-Wizard.

If you’ve never tried G-Wizard, take advantage of our free 30-day trial and check it out. You’ll find it is not just a great Feeds and Speeds Calculator, but an amazing time saver due to all the other great information it brings together for you.

Sign up today:

Have you got a tip you wish we’d build into G-Wizard? Let us know in the comments or email me via bob@cnccookbook.com!

Like what you read on CNCCookbook?

Join 100,000+ CNC'ers! Get our latest blog posts delivered straight to your email inbox once a week for free. Plus, we’ll give you access to some great CNC reference materials including:

- Our Big List of over 200 CNC Tips and Techniques

- Our Free GCode Programming Basics Course

- And more!

Just enter your name and email address below:

100% Privacy: We will never Spam you!

Recently updated on April 12th, 2024 at 03:03 pm

Bob is responsible for the development and implementation of the popular G-Wizard CNC Software. Bob is also the founder of CNCCookbook, the largest CNC-related blog on the Internet.