1 month by cncdivi

You haven’t provided a text to be rephrased. Could you please provide the details so I can help you better?

Dude, have you seen what these CNC machines cost?

CNC is one of my favorite things in the world, and it is amazing that an individual these days can actually have a full-blown CNC machine that’s more powerful than the machines used to put men on the moon right in their own garage. Heck, they’re capable of generating a decent living for you too, if you are a reasonably clever business person. But, the initial startup costs can seem steep.

How much does it cost to start into CNC?

We need to quantify the cost of a CNC Machine a bit before we talk too much about how to afford them. We have a whole article on CNC Machine Cost that will help too.

First thing is do you just want this thing for fun or do you want to eventually make some money with it?

Let me be more definite about making money–is that the reason you want the machine, or at least in the top 2 or 3 reasons? Do you plan to try to make some money in the relatively near term?

If money making is a fairly high priority, you’ll want a more capable machine.

Mind you, there are folks out there making some money with pretty inexpensive machines. Even really inexpensive machines like the Shapeoko routers. You can create some amazing things with these low end CNC’s. What’s hard with such a machine is any kind of volume. They do great work, but slowly. You’ll have a hard time leveraging them to make much money, though they’re awesome for pure hobbyists and as learning tools.

So, what sort of machine is the cheapest to consider if you do want to make some money?

My vote would be for something like a Tormach 440:

The Tormach PCNC 440: Good Starting Point…

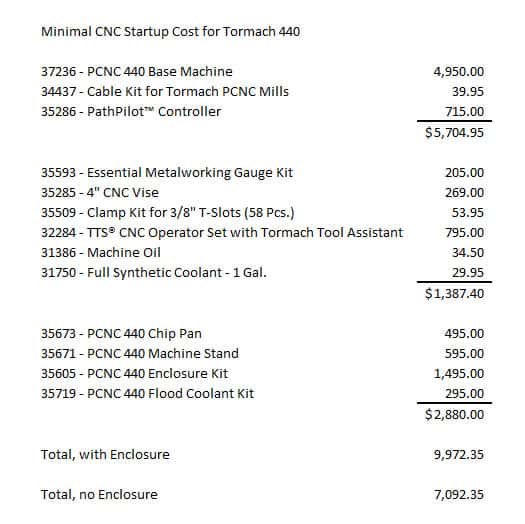

The 440 is an excellent starter CNC mill that’s capable of being productive enough to manufacture small runs of parts or to prototype. What does it cost?

Here’s how I would break it down:

Minimal CNC Startup Cost for a Tormach 440…

Okay, I see a bunch of you squirming out there–you’re uncomfortable.

About half of you are going, “Dang, that’s a lot of money!” The other half are going, “Dang, that seems cheap, how good can this machine really be at those prices?”

Yeah, I know, but let’s drill down on these questions and see. Let’s start on costs, and I’ve got two prices listed.

The first configuration is $9,972.35 (plus probably some shipping and other stuff) to get the turnkey package. I spec’d it out myself and deleted some items. For example, I assumed you can scare up your own old LCD monitor and keyboard and don’t need a new one from Tormach. Assuming you can do a little scrounging like that, you’ll be making chips pretty darned quickly after the truck drops off your machine in crates.

OK, but you’re good at making things, right? I hope you are if you’re going to buy a CNC!

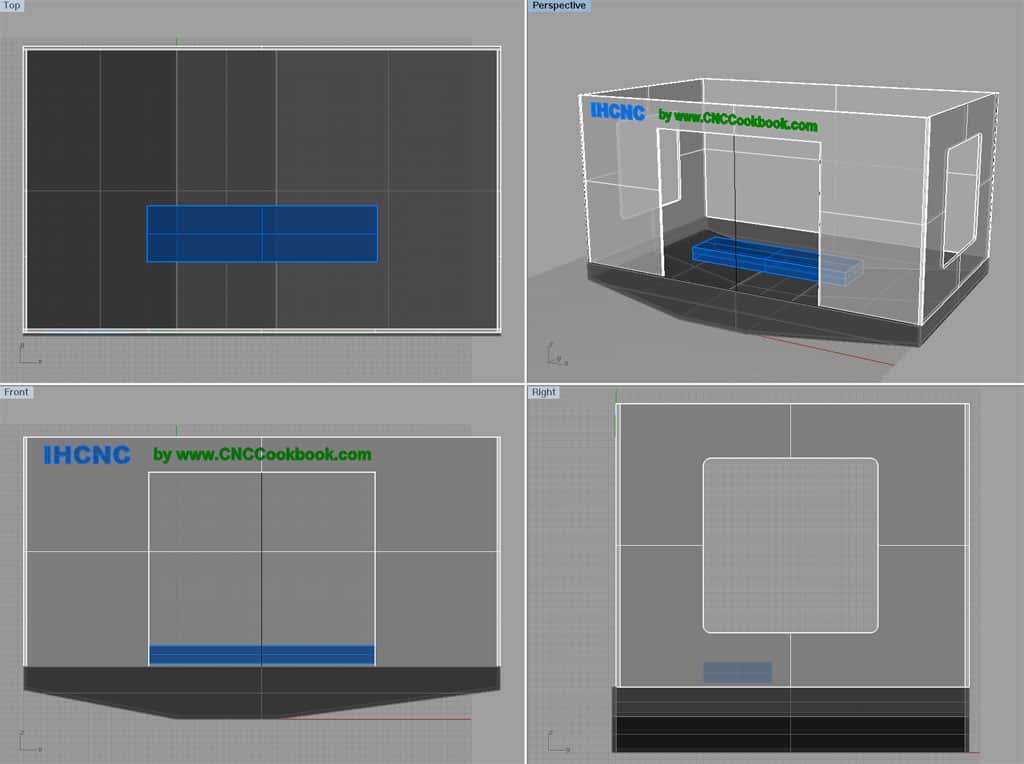

The second configuration is almost $3,000 cheaper at about $7100. It assumes you can build a stand, enclosure, and flood coolant setup. You’ll need to spend some time and probably a $200-300 in materials to get it done. It doesn’t take all that long, I built one for my original mill and it took me about 4 weekends of afternoons. That’s worth saving $3000, right?

I built it from plywood, coolant proofed it with marine epoxy, and it came out looking pretty nice. here are the plans I started with:

The 440 is a much smaller machine, so the enclosure will be correspondingly easier.

Some will wonder, “Do I need an enclosure or flood coolant?” Yes. You do. You’ll have chips all over your garage, tracked into the house, and pretty soon your significant other will have you building the doghouse you’ll be sleeping in if you don’t build an enclosure first. Trust me, been down the no-enclosure road, and it is so worth it and so not that hard or expensive.

It’d be hard to cut much else out of that list unless you happen to already own some of it. The rest is pretty basic. So, you need to be able to come up with $7,100 to pull this off.

Is This Tormach 440 Going to Be Good Enough?

Seriously, pal–is that machine good enough for me?

Now, to the other audience that asks, “Dang, that seems cheap, how good can this machine really be at those prices?”

Look, this machine is good enough to pay for itself, that much I am completely sure of, provided you can sell some business. You’ll get there just doing work for others, and it won’t take you forever either.

Is it the last machine you’ll ever need? Well, that depends on how much you want to grow your horizons, but probably not if you’re serious about making money. Eventually, if you do well, you’re going to outgrow this machine’s capacity. I recently ran an article that shows exactly how to calculate when it makes sense to upgrade to a more expensive machine. That article, BTW, convinced me that starting out with the cheaper machine and not rushing into something expensive is the right path. It’s going to take time to grow your business, and any excess capacity you’ve paid for is money you can’t spend to help grow the business in some other way. You might wish you had money to spend on marketing, for example.

The main reservation I would have about starting with the 440 is whether the parts you’re planning to make are just too big for it. I don’t know what your mission is, but I can certainly imagine it might involve bigger parts than a 440 can handle. You’ll be limited to making parts just a little smaller than it’s travels, which are 10″ x 6.25″ x 10″. If you need to make parts bigger than that, it’s possible, but it won’t be nearly as efficient as staying below that size. In that event, you’ll need to spend more to get to a machine with bigger capacity like a Tormach 770 or 1100.

What About Buying a Haas, New Or Used?

Sure. They’re awesome machines–much more powerful than the Tormachs. But, there are some issues you need to consider that are the reason I’m not recommending you start there.

First, a new one is hugely more expensive than the Tormach. Let’s try about $50,000 for a Super Mini Mill, which is one of their smallest machines. That’s just the machine, you will also need a bunch of tooling which will be a LOT more expensive than the Tormach tooling. You probably need to get your garage set up for 3 phase power, so you’ll need an electrician and a phase converter. This stuff adds up in a hurry–I’ll bet you’re into the better part of $70,000 before you’re ready to make chips.

Whoa! I am not going to be able to help you afford that in this one simple article–it’s too much.

Second, as I mentioned in the article on when it makes sense to upgrade, if you pay for capacity that is unused, you’ve spent money that could’ve been better spent elsewhere.

“Now hang on,” says a voice from the back seats–“I can get a used Haas VMC much cheaper.”

Yes, but are you qualified to evaluate the condition its in? What will it cost to get it rigged and shipped to your shop? <Silence>

Do you realize how much more expensive it is to repair the Haas if something is wrong? You can get a new replacement spindle for the Tormach for like $700, but the Haas spindle will cost you probably $4,000 – 5,000. <Gulp>

And how cheap is a Haas in good condition, anyway? I’m seeing them on eBay for circa $20,000 to $30,000. So, with a used machine, maybe your costs go from $70,000 to more like $40,000. That’s still a lot of money. You’ll have to make sure you have enough business in the near term to justify the added expense and you’ll need to be sure you don’t buy a lemon. I’d also encourage you to check that darned article I keep bringing up and run the numbers to see if this is really a better deal or not. Be sure to check whether it makes sense to get two Tormach machines (or even three) versus the Haas. In fact, you wouldn’t have to buy all 3 Tormachs up front, you can buy them as your business grows. A single person can handily keep even 4 machines running parts all day.

OK. I’ve decided what CNC machine I want. How can I afford it?

It’s good to have made the decision on machines. Now we just have to figure out how to get you into a machine.

Make it cheaper

We’ve touched on saving by building an enclosure and flood coolant system–$3000 off, check!

We talked about a used Haas, but used Tormachs are available too. They’re not as plentiful, but they do come on the market from time to time. You can save made 30-35% if you can find a used one. Be patient, and you will probably wind up with one of the larger Tormachs as they’ve just been around a lot longer and there are more of them than there are 440’s.

Save your pennies

It’s no fun, but it can work. Cut some costs and start putting away a little money every week. Bring a sack lunch to work. Quit ordering Starbucks mochas and drink cheap drip coffee. You’ll get there eventually.

Get a Loan or Lease It

This is how we buy things that are too expensive to buy outright, eh?

I hate the idea of debt, but sometimes its worthwhile. I do know that Tormachs hold their value pretty well, so if you needed to sell yours to get out from under the debt, that can be done.

Consider leasing too. I was just reading about a fellow in the Facebook Tormach User’s Group who leased a 770 and he said his payments were about $330 a month for 5 years.

Some combination of savings can pay for part of that, and for the rest, you could try a second job.

Don’t quit your Day Job, get a second job

Here’s a novel thought, what if you could pay off that Tormach within 1 year entirely using cash made with the Tormach? How much cash would be needed?

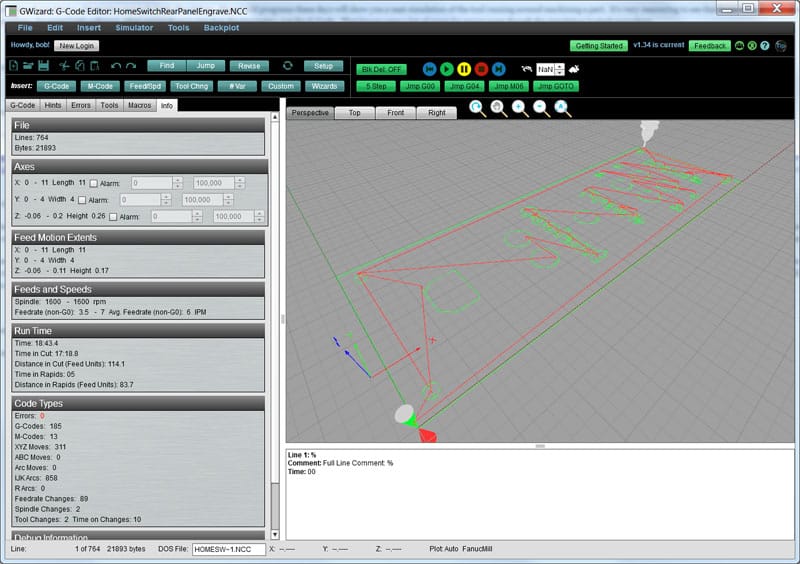

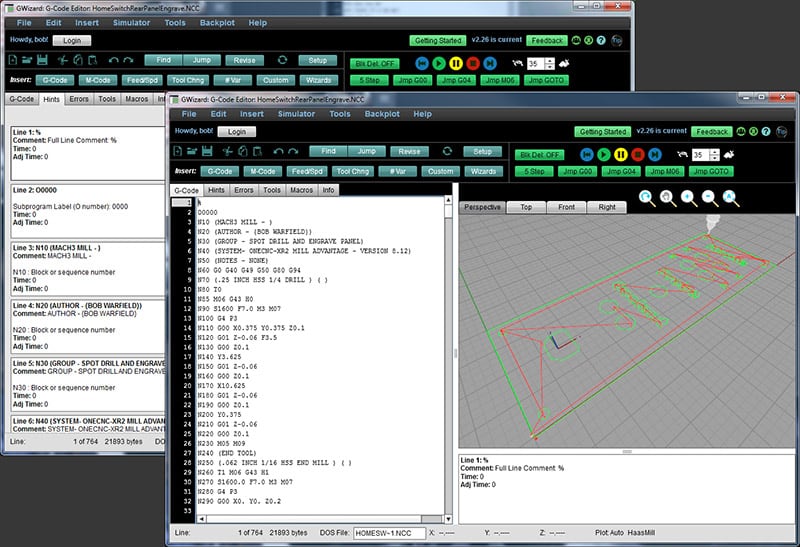

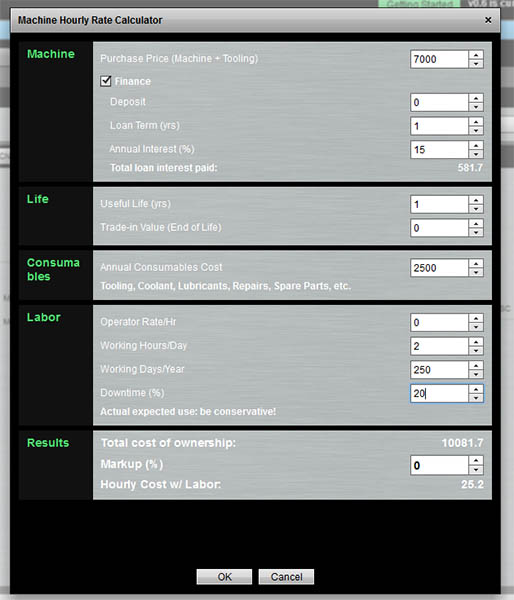

Turns out we can use the handy Machine Hourly Cost Calculator in our G-Wizard Estimator software to figure that out. Here’s what I got:

Can you make $25.20 an hour, working for 2 hours, 5 days a week with a 2 week vacation?

Can you make $25.20 an hour, working for 2 hours, 5 days a week with a 2 week vacation? If so, you can borrow the money at a 15% interest rate (credit card rate, lower ones are available) and have the note paid off at the end of 1 year. I know I worked at least those kind of hours in my “free” time while holding down a day job before I was able to get CNCCookbook to pay the bills.

What are some good second jobs?

I knew you were going to ask, so let me give you some ideas.

First, maybe your idea to make money with your machine can be accelerated and put into action right away so your payments are covered. If that’s possible, my work here is done.

But what if it’s not?

Let me start with something totally off the wall:

Be an Uber Driver to pay for your CNC Machine: Join the Gig Economy!

The Gig Economy–that’s the buzzword for things like Uber and AirBnB. They give you some kind of part time job that pays in exchange for bring you customers.

Got an extra room in your house and live in an area people like to vacation to? Super. Rent it out via AirBnB.

Got a decent car that measures up to their standards? Give people rides via Uber.

BTW, I’ve talked to a lot of Uber drivers because I’m fascinated by the whole thing. So far, every single one of them has been a reasonably well-to-do middle class person who is driving Uber to make some extra money. One senior citizen down in LA told me he did it because 2 nights a week and he meets interesting people and it covers his car payments. Another fellow who took us to the baseball game (dropped us at the door so we didn’t have to deal with parking) had an office job and did it two nights a week so he could be driving a high end Mercedes instead of a Honda. Figure you can make $19 an hour out of the $25’ish you needed to make your loan payments. That’s not bad!

Be somebody’s part-time freelance consultant

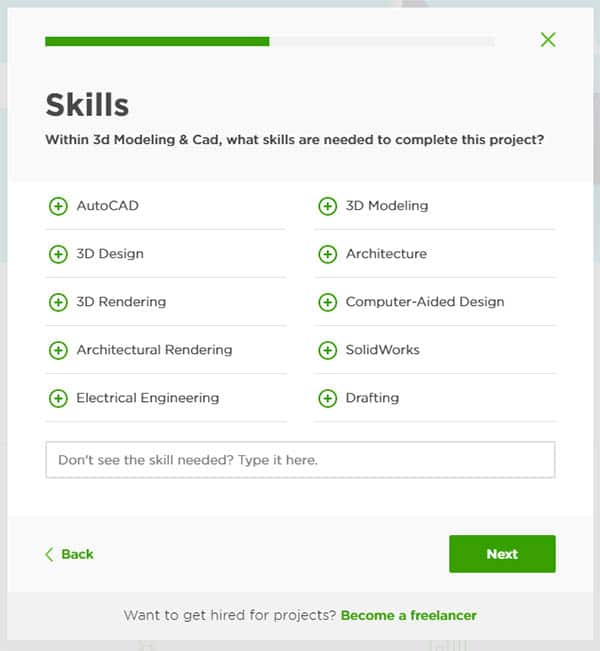

This is like the gig economy, but it’s also like doing what you do for a Day Job, just doing more of it in the off hours for an hourly rate. There are a bunch of web sites that are used to connect freelancers with gigs. Here’s an article about 15 of them, including sites like Upwork. I’ll leave it to you to judge whether this can work for you and which service seems the best, but many of the skills you may already have are in demand.

For example, you need to know CAD to get very far with CNC. Guess what? Upwork can get you CAD gigs–it’s one of the categories they’re specifically set up to handle. I entered it and was presented with this questionnaire of sub-skills:

You’ll also need to master CAM Software. Got that covered? Great, because there are gigs available on Upwork for CNC Programmers too. You can sell a variety of non-CNC skills too, I just mention these because CNCCookbook’s audience is likely to have CADCAM skills already. In this day and age, when you can get Fusion 360 for free and do fairly powerful things with it, you might easily pay for your first CNC machine doing CADCAM work for others.

You can freelance being a Job Shop too!

Don’t have the contacts to land orders for parts? You can freelance that too.

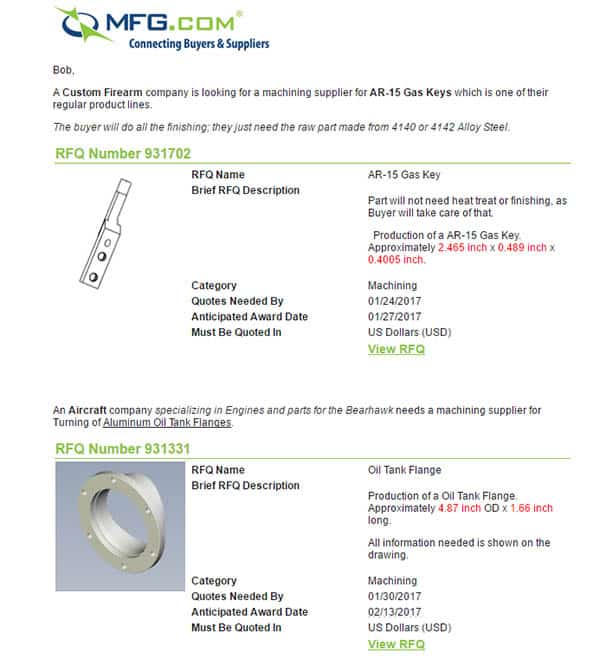

For example, join Mfg.com, it’s free. You’ll start receiving emails that look like this:

It’s worth getting a feel for the kinds of parts being bid on. You can’t actually bid or see the CAD models without paying, but you’ll get an idea. One thing is for certain, you will be expected to deliver the parts if they accept your bid. Make sure you can deliver without losing your shirt on the deal.

Sell a limited-production boutique product, possibly via Kickstarter

Ah, Kickstarter–one good one and your problems are all over paying for a machine!

But, it may not be that easy. And, as with the contract manufacturing, you will be expected to deliver.

I know a number of folks who’ve done extremely well with Kickstarter. It’s a matter of picking a product that audience wants. If you’ve got ideas along those lines, it’s promising and worth researching in depth. But, make sure you’re familiar enough with Kickstarter and its audience. Look for products that are at least in the same category or remotely similar.

Alternatively, take inventory of what you love. Some of those areas may harbor product opportunities. For each line item in your inventory of interests, note the online communities that love the same thing. Skip anything where you can’t find an online community, because those communities can b

e fabulous places to sell short-run products.

If the gift season is not too far away, it’s even better. I’d want to be ready to take orders by September 1 if it is a Christmas-worthy gift. I’ve written a number of articles about this kind of thing:

- 64 Fun Non-Tactical EDC CNC Gifts You Could Make This Holiday Season

- 18 CNC Jewelry Gift Ideas

- Every Day Carry: New Ideas for CNC Projects

For a great write up on an area that’s perfect for this sort of thing and has an active online community, see my article on CNC Flashlights.

Conclusion

You’re the only one who can say for sure whether you can afford a CNC Machine and which one is right for you. This article has been all about how to think about the process and perhaps some ideas that might help. There are lots of possibilities I haven’t covered. Keep an open mind and plan your CNC future.

Readers, what ideas can you contribute for how to pay for a CNC Machine? Tell us in the comments!

Like what you read on CNCCookbook?

Join 100,000+ CNC'ers! Get our latest blog posts delivered straight to your email inbox once a week for free. Plus, we’ll give you access to some great CNC reference materials including:

- Our Big List of over 200 CNC Tips and Techniques

- Our Free GCode Programming Basics Course

- And more!

Just enter your name and email address below:

100% Privacy: We will never Spam you!

Bob is responsible for the development and implementation of the popular G-Wizard CNC Software. Bob is also the founder of CNCCookbook, the largest CNC-related blog on the Internet.