2 months by cncdivi

I enjoy discovering the Best Practices of nearly any sector because I’m curious about what sets the industry leaders apart.

There’s an audience that wants to believe they just got lucky and that they’re no better than anyone else, and there are elements of truth to that–to be really successful does require some luck. But what I’ve found as an entrepreneur who has helped build 8 businesses so far, is that most of the time the Top Dogs did things a little differently. The real trick is in understanding exactly which of those things really mattered.

I just went over the results of Modern Machine Shops annual Top Shops benchmarking survey. Kudos to these guys for doing this work–they’ve unearthed a wealth of useful information about various shops and tried to analyze what the major trends are that set the Top Shops apart from the rest. I will leave it to you to read their conclusions. What I want to do here is present my own analysis of their data, which has a little bit different spin. As I mentioned, the real trick is in understanding which things Top Shops do differently matter. I do a lot of number crunching in spreadsheets, and have even developed specialized calculation software for specific difficult number crunching problems. What you have to do is come up with an algorithm to separate the signal from all the noise. In this case, what I was interested in understanding is what the majority of Top Shops were doing that the majority of Other Shops don’t. So there were two criteria:

- More than half the Top Shops had to have taken on the practice. Otherwise, it’d be hard to say that particular practice would be broadly successful if Other Shops tried it.

- At the same time, the likelihood of taking on the practice had to be hugely higher for a Top Shop than an Other Shop. In other words, it had to be something fairly unique that Top Shops were doing that Other Shops were not.

Sounds simple, but the results were interesting and present some different conclusions than MMS gave in their write up, so let’s dig in.

Top Shops Don’t Have Some Special Structural Advantage

For that audience that wants to believe the Top Shops got lucky, better think again. It’s easy to sit back and assume they’re just bigger shops, or they just lucked into better contracts. All the data about how they run their businesses would be just noise if this were the case. But, the data says otherwise:

- Top Shops manufacture similar quantities of parts as other shops.

- They produced a median of 35,000 parts a year versus 25,500 parts.

- Their batch sizes were slightly larger–50 vs 37, but in general, all these shops are High-Mix/Low-Volume. That’s how customers want it and that’s the business they’re offering.

- They made approximately the same number of different parts (SKU’s): 500 versus 400. So, Top Shops had to deal with more variety than Other Shops.

- Top Shops have similar numbers of machines on their Shop Floors.

- 12 machines versus 8.5

- 70% capacity utilization versus 65%

- Average age of machine is 7 years versus 9–it isn’t that the Top Guys have a bunch of shinier new machines.

- Same order lead time: 21 days median

- Similar On-Time Delivery: 95% vs 90%

- Similar Quality Yield: 98% vs 95%

- Similar Customer Make Up:

- 25 vs 21 active customers

- 80% of business coming from 15% of customers (Sound familiar?)

- Similar Workforce:

- 26 employees at Top Shops vs 22 employees

- Slightly lower overhead–76% of Top Shops employees are directly involved in manufacturing versus 64% at Other Shops

- Very similar wages–Top Shops pay Setup and CAM Programmers the same and $1 less per hour for Operators.

The point is, your shop has the makings of a Top Shop, they’re just running their businesses a little differently. And what a difference it makes:

- Top Shops have a 69% higher profit margin.

- They are growing 150% faster than Other Shops.

Like they say, it’s hard to argue with success. Let’s try digging into what they’re doing differently.

Machine Differences

Compared to Other Shops, Top Shops are 69% more likely to have Four Axis Positioning Only capability and they are 102% more likely to have Turn-Mill machines.

Remember, we’re sticking to things the majority of top shops do that relatively few Other Shops do, so more than half the Top Shops have these advantages over their competitors. It’s not that hard to pick up some Fourth Axis capability, maybe it’s time you had a look into it?

Cutter-Related Advantages

Top Shops are 84% more likely to have High Pressure Coolant. This is a trend MMS says has been growing steadily, and it’s something Other Shops need to start looking into. Similarly they are 65.2% more likely to have Through Spindle Coolant.

Our G-Wizard Feeds and Speeds Calculator will show you graphically how much High Pressure Coolant and Through Spindle Coolant can increase your throughput. Use G-Wizard as a simulator to see what these options could do in your shop.

Top Shops are 50% more likely to do Tool Inventory Management. It’s tough to manage something if you have no idea what’s going on with it. Tooling is a big investment for shops. What do the Top Shops get out of all Tool Inventory Management? If you look at tthe % they spend on tooling, they were able to bring it down from 5% at Other Shops to 3%. That’s a whopping 24% savings that goes straight to the bottom line. You gotta figure it won’t take long for that kind of investment to pay for itself.

Workholding

Only one thing jumps out enough here–Multiple Workpiece Fixturing. Yes, the Top Shops are more likely to have the toys–Pallet Changers and Quick Change Devices, but they’re not enough more likely. The only other thing that was even close was Quick Change Devices–presumably fixture plates are the biggest example. But, 80.8% of Top Shops have Multiple Workpiece Fixturing which made them 50% more likely to have it than Other Shops. Presumably you just have to get beyond using a milling vise to reap this advantage.

Check out the Fixture Calculator in our G-Wizard Estimator to get an idea what kind of advantage this could mean for you on a particular job. And remember–with low volume high mix jobs, you have to be careful when and where you invest in Fixturing so it pays off. The Fixture Calculator is tailor-made to help solve that problem.

I suspect that Low Volume world we live in accounts for some of the lack of excitement in this category.

Software

Everybody has CAD, everybody has CAM, yeah, Top Shops have ERP but so do a lot of Other Shops. As a CNC Software provider, I love this category, but frankly, so many shops have software, it’s become a must have situation. If you don’t have one of the categories, you’re at a signficant disadvantage. The competitive axis here is on how well your software is working for you. We offer software in the Toolpath Simulation and Job Estimating categories. Here’s what the MMS Survey had to say about those:

- 54% of Job Shops use Toolpath Simulation Software and they’re about 28% more likely to have it than Other Shops. Like I said–it’s a must have. If you aren’t using a Simulator yet, check out our G-Wizard Editor product. Our customers recently helped us quantify the benefits, and we were surprised at how much value they were getting from Toolpath Simulation. It’s no wonder it’s become a must have tool in the shop.

- 42.3% of Top Shops are using Job Estimating Software–about 20% more than Other Shops. Here again, a lot of Shops have this advantage, so you should be looking into it.

On the topic of Job Estimation, there was one statistic that really jumped out for me: Top Shops win fewer quotes than Other Shops!

Top Shops are winning 53% of the jobs they bid while Other Shops win 65%. That tells me the Other Shops are bidding low to get the business while the Top Shops are better at getting higher margin business. To get the cream off the top you need a tool like a Job Estimator to be able to manage your quotation process closely enough so you know just where to price your bid. I suspect the Top Shops that didn’t indicate they had the software had a sophisticated home grown solution based on spreadsheets or similar tools that gives them this advantage.

Ancillary Machining Equipment

We skipped the category of Inspection–not enough action there. Ancillary Machining Equipment is a hotbed with two big standouts:

- Top Shops connect their machines via Ethernet. 62% of shops have done so and Top Shops are 61% more likely to do so than Other Shops. Sneaker Net, USB Keys, and RS-232 DNC are just not cutting it. We live in a connected world, so CONNECT!

- Top Shops equip their machines with Mist Control. 50% of them have it, which makes them 84% more likely to have it than Other Shops.

Honorable mention goes to Machine Condition Monitoring. Once that machine is on the Ethernet, you can do more than just ship gcode around. Only 25% of Top Shops are using Machine Condition Monitoring so far, but this is a whopping 168% more likely in Top Shops than Other Shops. It doesn’t take a lot to get your machines networked, and it opens a lot of doors for future opportunity once you’ve done so.

Big Differences: Process Improvement

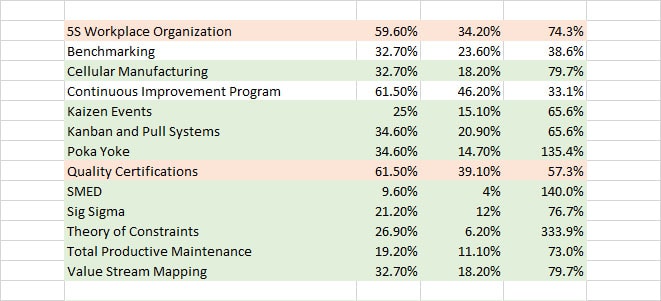

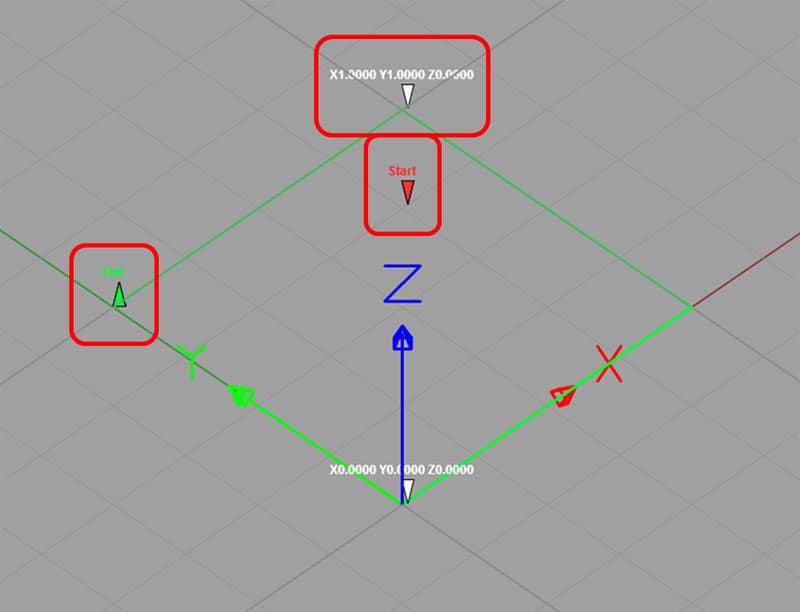

Much as we would all like to buy some shiny silver bullet technology or gadget, often it is process that wins the day. Working Smarter is so much more effective than just Working Harder. The Top Shops rang the bell in almost every process area. In fact, I want to give you my spreadsheet numbers right here:

Pink = Most Urgent, Green = Urgent Investment Opportunities…

The Top Shops are beating the Other Shops by more than 50% in almost every category except Benchmarking (because not enough more Top Shops do it than Other Shops) and Continous Improvement (because enough Other Shops are already doing this one). The two biggest standouts are that over half the Top Shops have a 5S initiative and a Quality Certification such as ISO. If you don’t already have those two, I would get them underway ASAP.

The next most popular among the Top Shops are Cellular Manufacturing, Kanban, Poka Yoke, and Value Stream Mapping. We’ve covered almost all of these in our Lean Manufacturing Series if you want to get a quick intro to any of them.

Of all the categories in the MMS Survey, this is the one that really leaped out as showing what the Top Shops are doing differently. It’s really worth thinking about it carefully.

More Big Differences: Marketing

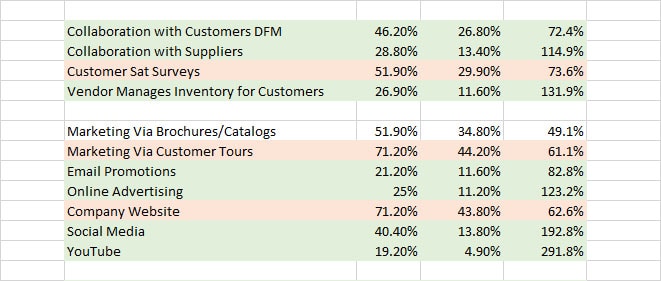

It’s tough to be a Top Shop if you can’t sell to customers, so it makes sense to ask whether Top Shops market any differently than Other Shops. Not surprisingly, of course they do!

- 71% of Top Shops have a web site. They’re 63% more likely than other shops to do so. In this day and age, you’re leaving money on the table if you don’t make it easy for new business you have no other way to network with to find you.

- 71% of Top Shops use Customer Tours as a marketing tool versus 44% of Other Shops. I don’t know whether the Other Shops don’t offer or just haven’t made their Shops something they’re proud to show a customer, but they’re missing a wonderful opportunity to build a lasting relationship if they’re not bringing customers in for a tour.

- 52% of Top Shops do Customer Satisfaction Surveys. They’re 74% more likely than Other Shops to do so! Here at CNCCookbook we’re constantly taking customer’s temperature and asking for their feedback. We learn so much from it we consider it a competitive advantage. I can’t imagine any business wanting to be without such an advantage.

This was another one like Process that had a lot of near misses, so here are my full results:

Pink = Most Urgent, Green = Urgent Investment Opportunities…

Some of the standouts for me were:

- YouTube–not that many shops experimenting with it, but Top Shops are about 3x more likely to do it than Other Shops.

- DFM (Design for Manufacturing). These shops are actively helping customers understand how to change their part designs so they’re cheaper to manufacture. Our G-Wizard Estimator product as well as the CADCAM Wizards in G-Wizard Calculator give DFM advice. Helping a Customer this way is surprising–“You’re helping us to pay you LESS money???” But it is that surprise that convinces the Customer you’re going to be great to partner with for the long-term.

- MMS was taken with how many are using Social Media, and I agree. Get a Facebook page today, you’ll be surprised what comes in through that door.

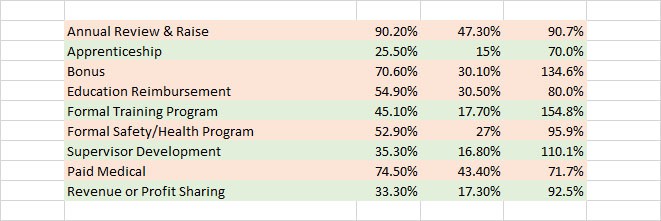

Still More: Employee Compensation

This is another one that had so many hits, I have to share my full list:

Top Shop employees are invested in the success of the business…

Top Shops are approaching how they pay their employees dramatically differently than Other Shops. It’s not about the hourly rates–Top Shops pay the same or a little less. It’s about giving the employee the incentive to care about making the business more successful and it’s also about getting the employee to feel like the business treats them well. More benefits, but also benefits tied to the performance of the business such as a bonus or revenue sharing can really make the difference. This one goes hand in hand with the process improvements. As anyone who has been through Lean Manufacturing knows–everyone has to want to make it work or it won’t.

Conclusion

There’s a tremendous number of great opportunities here to learn from the Top Shops. What they’re doing differently are things any shop can do–you just have to choose to do them. Why not get started today, at least with some Process or Marketing initiative for your shop?

Like what you read on CNCCookbook?

Join 100,000+ CNC'ers! Get our latest blog posts delivered straight to your email inbox once a week for free. Plus, we’ll give you access to some great CNC reference materials including:

- Our Big List of over 200 CNC Tips and Techniques

- Our Free GCode Programming Basics Course

- And more!

Just enter your name and email address below:

100% Privacy: We will never Spam you!

Bob is responsible for the development and implementation of the popular G-Wizard CNC Software. Bob is also the founder of CNCCookbook, the largest CNC-related blog on the Internet.

Every table has 3 columns of data, would you care to explain them?

Sure Andrew. Left column is % of Top Shops who follow the practice. Middle is % of Other Shops. Right is % difference–how much more likely are the Top Shops to follow the practice.

Thanks Bob. Later I got that myself, but at first the numbers were a bit overwhelming.

Good analysis

once again, a great article. this gives me a lot to think about, thanks!