2 months by cncdivi

I’ve just shared version 2.30 of the G-Wizard Calculator (you can download it here) which features some impressive new additions. Please take a look:

New OD Turning CADCAM Wizard

The CADCAM Wizard’s are designed to get you feeds and speeds in a form that is ideally suited for your CAM program and with as few keystrokes as possible. The new OD Turning CADCAM Wizard is the first one we’ve done for lathes. Let’s go through it from top to bottom.

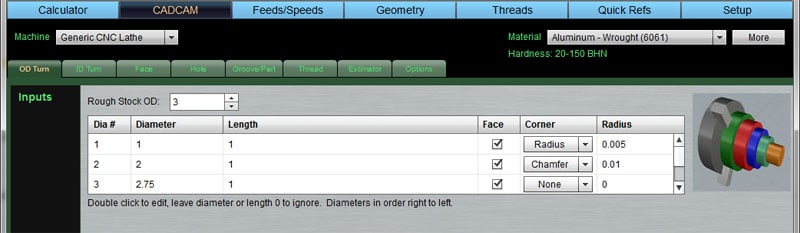

First, here are the inputs you need to give it to get some answers:

OD Turn Wizard Inputs…

To use the OD Turn Wizard, you’ll need to tell it your Rough Stock OD (Outside Diameter). Directly below the Rough Stock OD is a table of up to 6 diameters you can turn. This saves you the trouble of entering them one at a time. Seems like most turning jobs will require more than one diameter.

For each diameter, you indicate the diameter, length along the axis for that diameter, whether to face the right edge, and how to prepare the corner of the right edge. Corner preparations include Radius and Chamfer. We’ll use a similar UI to generate g-code in our Conversational Wizards for GW Editor, but for now, this is only available for Feeds and speeds.

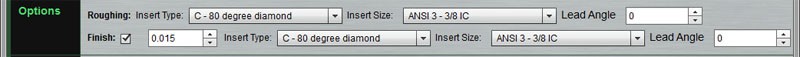

Next up are the various options for the cut:

OD Turn Wizard Options…

The options are essentially about what kind of insert and lead angle for that insert you plan to use for the roughing and finishing passes. The finishing pass is optional. You can specify all the ANSI standard insert types and sizes.

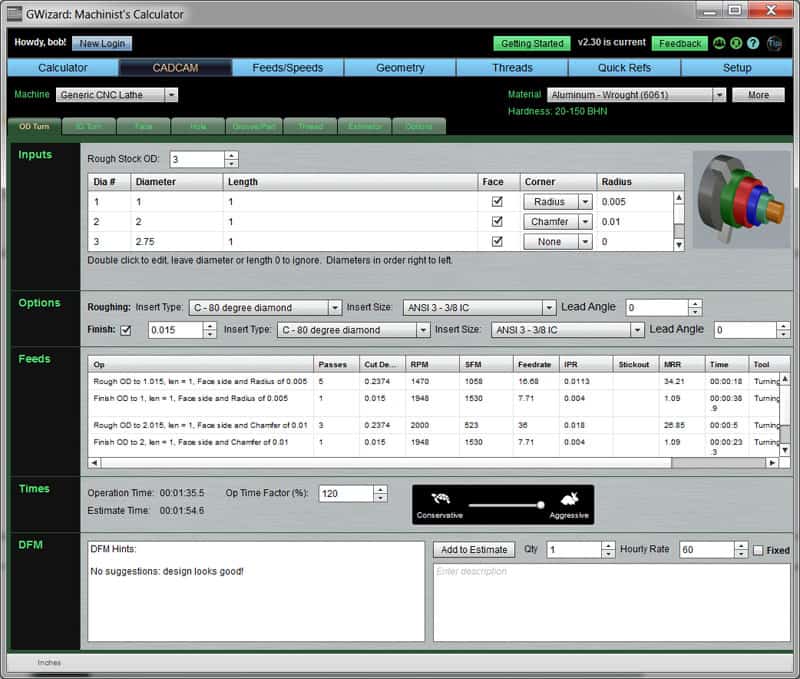

Given those inputs, here are the results you get back:

OD Turn Wizard…

The table of results (labelled “Feeds) gives everything you’ll need for CAM or hand programming. The operation is described along with how many passes, best cut depth, the tool, insert, and all the other parameters. Both RPM and SFM and Feedrate and IPR information is given since we often like to program lathes with CSS (constant surface speed) and feedrate per revolution.

For estimation purposes (remember CADCAM Estimator is an integrated add-on module for G-Wizard Calculator), we calculate the MRR, operation time, and so forth, and you can add all these OD Turning ops to your estimate with the “Add to Estimate” button.

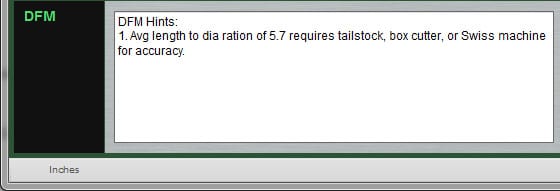

DFM: Design for Manufacturing Hints

The OD Turning Wizard also gives Design for Manufacturing Hints down in the little DFM box. For example, if we specify an especially long overhang on a part, we might get this message:

Design for Manufacturing Hints…

G-Wizard knows when your parts avg diameter to length ratio is such that a tailstock will be needed. It puts this into the DFM area because a part that requires a tailstock will be a little more expensive to make than one that doesn’t, all other things considered. Note that there are alternatives, for example using a Swiss machine or a box cutter. These are other approaches to cutting long skinny parts without getting too much deflection. All of the CADCAM Wizards have a collection of DFM rules that can be triggered to help you keep your parts as simple as possible and no simpler.

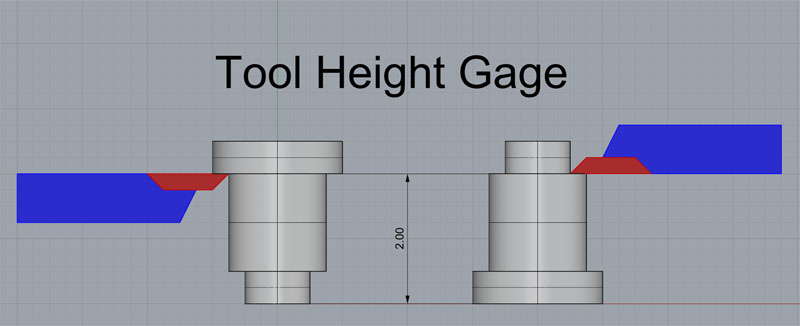

Chamfer Geometry for Endmills

This is a feature that is requested fairly often. It was the #2 most requested feature (after mobile device support) on our User Portal.

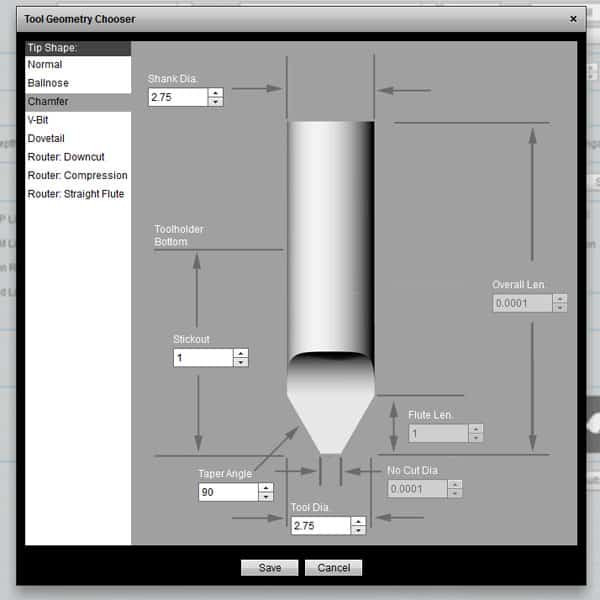

I had to do some fairly major Tool Crib overhaul work to handle some other niggling issues, so I wanted to make adding geometries easy going forward as well. The new Chamfer Geometry feature is super easy to use. Just select an endmill, click the “Geometry” button, and select the “Chamfer” geometry from the popup:

Chamfer Geometry…

The Taper Angle for the Chamfer is the included angle, which means it includes both sides. So, 90 degrees gives a true 45 degree chamfered edge.

If you would like to try these new features just download the latest G-Wizard. If you’ve never tried G-Wizard, be sure to sign up for our free 30-day trial.

Like what you read on CNCCookbook?

Join 100,000+ CNC'ers! Get our latest blog posts delivered straight to your email inbox once a week for free. Plus, we’ll give you access to some great CNC reference materials including:

- Our Big List of over 200 CNC Tips and Techniques

- Our Free GCode Programming Basics Course

- And more!

Just enter your name and email address below:

100% Privacy: We will never Spam you!

Bob is responsible for the development and implementation of the popular G-Wizard CNC Software. Bob is also the founder of CNCCookbook, the largest CNC-related blog on the Internet.

![Chamfer Mill Speeds and Feeds [ Chamfering Tool Guide ] A 3d model demonstrating the various dimensions of a box, featuring a chamfering tool for precise angles.](https://www.cnccookbook.com/wp-content/uploads/2018/07/img_5b4e249ef1f99.png)

![Eccentric Turning and Offset Turning [ Lathe Tips ] Two disassembled metal machine parts and a screw on a granite surface, showcasing eccentric turning techniques.](https://www.cnccookbook.com/wp-content/uploads/2021/06/eccentricsplitfinished.jpg)

![Free Lathe Feeds and Speeds Calculator [ Turning ] Icon button with CNC lathe](https://www.cnccookbook.com/wp-content/uploads/2023/10/TintedLathe-150x150.jpg)

Is very useful and can u run as a simulator on the P C