2 months by cncdivi

A well-done, smooth metal surface has an appeal of its own. On some occasions, machining marks may be desired for aesthetic purposes (I intend to create a small software utility someday to pattern these marks!), but usually, a more polished or satin finish is preferred.

Given my predisposition to avoid unnecessary effort, I’m always scouting for efficient tools and techniques that ease the physical work involved in my shop duties. Labor-saving can come in many forms, from learning the right way to use a file to owning the correct power tools.

For instance, I utilize a 12″ disc sander that I assembled and use regularly, along with several miniature belt sanding air tools that function similarly to a file, with a belt width of approximately 1/4″. I always have a deburring tool secured in another air tool, and a couple of easily accessible angle grinders with both an abrasive wheel and a wire wheel.

My workshop also houses a blasting cabinet, a vibratory polisher (which is my personal favorite for labor-saving, although it doesn’t work for all parts or finishes), a potent 5 HP buffer, a large drawer filled with files of all shapes and sizes, numerous scotchbrite pads, flap wheels, and so on. I think you get the picture.

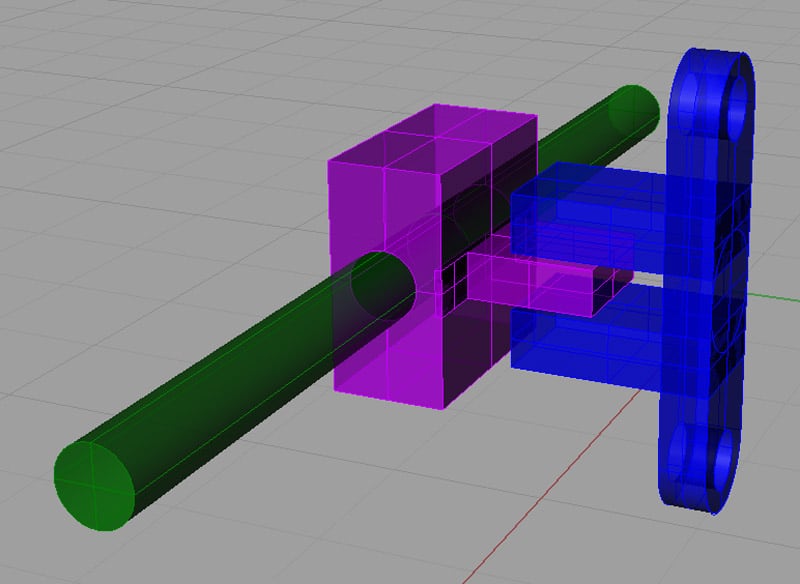

Naturally, when I came across these burnishing machines over on the Garage Journal (thanks to Monte for posting about them), I was intrigued. Here’s a video that shows the idea:

The machine is a hand held power tool aimed at strategically placing scratches on the material with an abrasive to create a satin finish. They make it easy to change the grits and offer a variety of styles.

I’ve used a random orbital palm sander to apply a satin finish, and they work pretty good, but this tool looks to me like it would be faster and easier, especially for welded/fabricated projects like the one shown in the video. Here’s a couple more pictures of this type of tool:

Metabo Burnishing Machine

Flex Burnishing Machine

These tools are German made and not exactly cheap, but they sure look handy.

Like what you read on CNCCookbook?

Join 100,000+ CNC'ers! Get our latest blog posts delivered straight to your email inbox once a week for free. Plus, we’ll give you access to some great CNC reference materials including:

- Our Big List of over 200 CNC Tips and Techniques

- Our Free GCode Programming Basics Course

- And more!

Just enter your name and email address below:

100% Privacy: We will never Spam you!

Bob is responsible for the development and implementation of the popular G-Wizard CNC Software. Bob is also the founder of CNCCookbook, the largest CNC-related blog on the Internet.

![Unlock the Secrets of Surface Finish Symbols [Must-Read Guide!] Surface Finish Symbols](https://www.cnccookbook.com/wp-content/uploads/2021/10/SurfaceFinishCheatSheeet.jpg)

![Fly Cutter: Ultimate Surface Finish Rewards [Complete Guide] A detailed drawing of a machine with a fly cutter attachment.](https://www.cnccookbook.com/wp-content/uploads/2017/09/WidgitFlyCutter.gif)

![Milling Surface Finish: Complete Guide [Tips & Secrets] A golden robot is milling on a white background.](https://www.cnccookbook.com/wp-content/uploads/2019/01/DancingRobot.jpg)