2 months by cncdivi

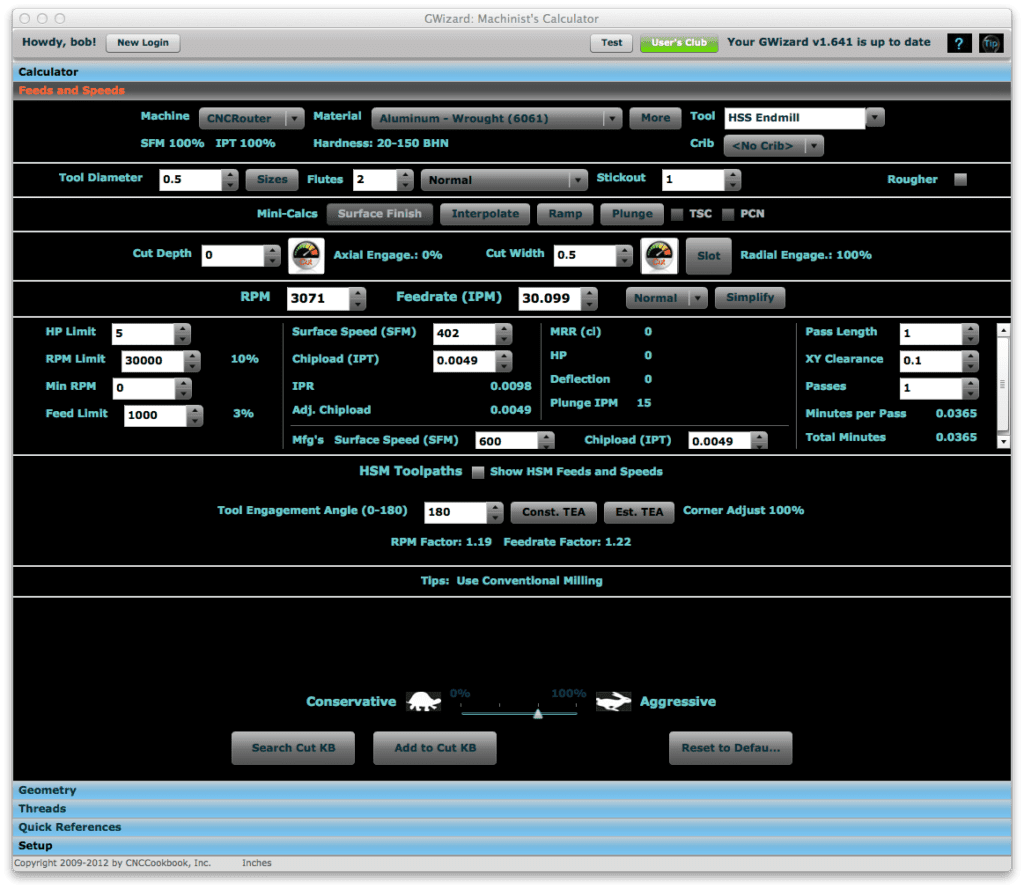

The recent update to the G-Wizard Machinist’s Calculator has added a new feature that simplifies the process of using Manufacturer’s Data for feeds and speeds calculations. Check out the screen shot for a peek into the feature.

G-Wizard Feeds and Speeds Calculator

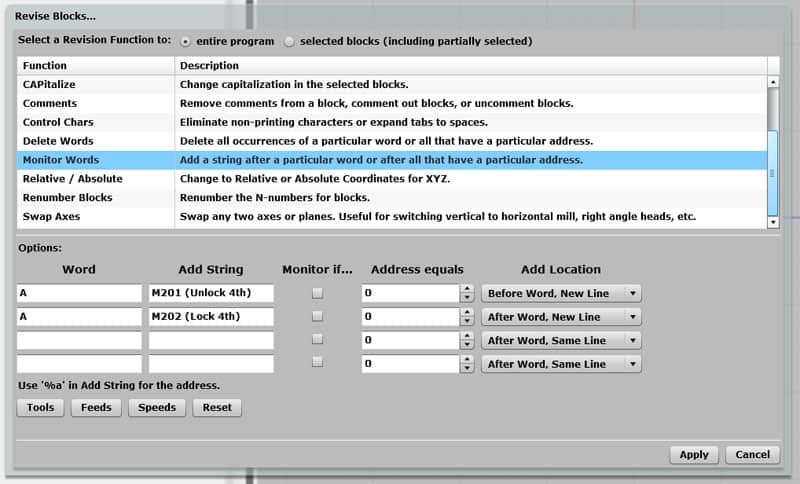

Notice the new area right above the HSM Toolpath section that has the label “Mfg’s Surface Speed”. There is a place to enter chip load just to the right. Using these two fields, you can easily give G-Wizard the manufacturer’s recommended surface speed and chip load for the particular tool or cutter you are using. Previously, the only way to do this was to create or download a full custom surface speed and chip load table for the tool, which requires quite a bit more effort. Let’s look at a couple of key questions to gain a better understanding of this feature:

What is the difference between the manufacturer’s data for surface speed and chip load and G-Wizard’s listing of surface speed and chip load?

This is a very important point to understand. Think of the process G-Wizard goes through as consisting of two parts:

1. Determine a surface speed and chip load without regard to the cutting conditions based on the tool type and material.

2. Adjust that surface speed and chip load to fit the cutting conditions.

Cutting conditions would be things like the cut depth, cut width or coolant options such as Through Spindle Coolant. If the cutter is deep down and cutting the full cutter diameter, it has to run much more conservatively and slowly than if it is taking a very shallow cut that is a fraction of the tool’s diameter wide.

Given this understanding, the Manufacturer’s Data is the surface speed and chip load without considering cut conditions. The Surface Speed and Chipload shown above it reflect G-Wizard having adjusted that starting point for the cutting conditions.

How did G-Wizard operate with the manufacturer’s data before this feature was added?

If you don’t enter anything into the Manufacturer’s Data, G-Wizard uses an idealized estimate of what these should be. This estimate is arrived at by a statistical analysis of a lot of different tools that are similar. By similar, that means tools that are made of the same material, have the same coating, same number of flutes, and so on. In practice, the analysis is fairly conservative and seeks to combine data from aggressive manufacturers with that of conservative manufacturers. It works well for general purpose use, but if you’re using more premium tools, you may find you can go faster by using the manufacturer’s recommendations.

While G-Wizard does a great job for most tools, the biggest opportunity to get ahead with Manufacturer’s Data is when using indexable tooling. The reason is that there are so many different inserts available and GW just uses a “one-size-fits-all” estimate. With this new feature, just look up the recommended chip load an surface speed for your insert, put them in, and you’re good to go.

If I have the Manufacturer’s Recommendation, why do I need G-Wizard?

I see this one a lot. The reason goes back to that 2 step process where we first determine an idealized recommendation and then adjust for the actual cutting conditions. The manufacturers don’t help you do this very well. Often, they throw out a pretty broad range of numbers and expect the machinist to try to estimate where in the range a particular cut should be. There is a lot of benefit in making it more of a science. G-Wizard considers nearly 50 variables when formulating its feeds and speeds recommendation. The reality is the manufacturers can’t reflect that much complexity in a simple set of tables. Each table can only show 2 or 3 variables at once, for example. To consider 50 variables would require an awful lot of tables!

Which data from the manufacturer do I need?

Avoid the data that’s been adjusted too much for cutting conditions. If they have a table for general purpose milling and another for milling slots, use the general purpose table. All you need is the surface speed and chip load for the particular tool and diameter of that tool you are using. If the manufacturer gives a range of values, take the most aggressive values and let G-Wizard adjust those downward based on the cut conditions. If you want to be more conservative than that, take a value that is more towards the higher end of the range and certainly past the midpoint.

Would I ever want to enter the old style manufacturer’s data?

By old style, I mean loading up the full chip load table or downloading it.

The answer is that if you use a lot of tooling in different diameters and always from the same brand, you’re better off to enter the full table once than to keep looking up surface finish and chip load for every different cutter size.

OTOH, if you use a lot of different insert types, the new ability to enter that data right on the front page of the feeds and speeds calculator should save you a lot of time.

How does this feature work with the Tool Crib?

We save any Manufacturer’s Data to the Tool Crib. So, if you like using the Tool Crib feature, you’ll only need to enter Manufacturer’s Data once, save that tool in the crib, and then it’ll be there for you to access any time you want.

Conclusion

This new feature makes it a lot easier to take advantage of the greater performance available from the best tooling. Whether you use the Tool Crib to remember the Manufacturer’s Data, look it up as needed, or maybe even stick it in a notebook, it’s very quick to plug it in and use it. Meanwhile, G-Wizard will help you get even more performance by doing a much better job factoring in cut conditions than any tooling catalog can do.

The biggest bang for the buck from this feature will come for indexable tooling. If you’re using inserts on the mill or lathe, you need to plug in your Manufacturer’s Data to get the best possible performance out of your tooling.

[/et_pb_text][/et_pb_column][/et_pb_row][/et_pb_section]Like what you read on CNCCookbook?

Join 100,000+ CNC'ers! Get our latest blog posts delivered straight to your email inbox once a week for free. Plus, we’ll give you access to some great CNC reference materials including:

- Our Big List of over 200 CNC Tips and Techniques

- Our Free GCode Programming Basics Course

- And more!

Just enter your name and email address below:

100% Privacy: We will never Spam you!

Bob is responsible for the development and implementation of the popular G-Wizard CNC Software. Bob is also the founder of CNCCookbook, the largest CNC-related blog on the Internet.

![Using Your Mill CAM For the Lathe and Turning G-Code [ Sneaky Trick ] A screen shot of a computer screen displaying a circuit diagram with SEO keywords: Mill CAM](https://www.cnccookbook.com/wp-content/uploads/2018/10/Step5XtoZZtoX.jpg)