1 month by cncdivi

Let’s assume you have a working CNC machine that you’ve just acquired, but that you know very little about CNC. Let’s further assume it is a mill and that you will be focused on cutting metal. You’re ready to start milling custom chopper parts, build a tool changer, or scratch build a Colt 1911 handgun. With CNC, you can build almost anything and you’re chomping at the bit to get started on your pet projects.

Not so fast! Remember, you just got the machine and you’re a beginner. You’re not ready for those projects yet.

After that, here are 10 things you should focus on to maximize your chances of becoming quickly successful:

1. Buy Some Decent Cutters

Don’t get the package of assorted sizes of cheezy imported cutters. You also don’t need the solid green unobtanium aerospace cutters from Men-In-Black-Cutter-Supply. Get some decent cutters from a reliable source that has reasonable prices. I like Lakeshore Carbide for example. Try for a name brand, one that’s on sale.

If you don’t know what the good brands are, check out our End Mill survey. It’ll show you which brands are most popular and have the highest customer satisfaction.

Get yourself a few sizes:

– 1/2″

– 1/4″

– 3/16″

Nothing smaller at this stage until you’ve learned on less delicate cutters. Buy 2 or 3 flutes for aluminum and some 4 flutes for everything else. I’d get 3 of each in each size to start. You are going to break some cutters, so get over it and accept the idea. It’s a good thing at this stage to remind you to wear your safety glasses because you will break some cutters!

While you’re at it, buy a full twist drill assortment. HSS from a decent brand on sale will work fine. I like the idea of replacing the ones I break with cobalt over time. That way my most-used sizes wind up higher quality. And one more twist drill tip–buy screw machine length, not the usual jobber length bits.

The screw machine length bits are more rigid and you will seldom drill super deep holes anyway.

2. Get a Decent Vise, a Clamping Kit, and a set of Parallels

Yeah, I know, vises are expensive, but workholding is very important.

Get a decent Kurt-style vise for your mill. It’ll be money well spent on a valuable piece of tooling that will last for years. In my shop I have used Kurts purchased from eBay and a couple of brand spankin’ new Glacern vises. There is sneaky stuff that goes on when you clamp a workpiece into the vise. If you don’t have a good one, the workpiece will shift and you’ll be wondering what happened.

You’ll need a way to mount your vise to the T-slots of your table, so you may as well get a clamping kit too. Any old kit will do. Buy the one that is on sale at your favorite supplier. These are step clamp kits that give you a basic set of cnc clamps. There are many other types, and you can expand your collection as needed over time.

Lastly, you’ll need a set of parallels, at least until you get proficient at making step jaws.

CNC Routers are a different story. You’ll mostly be clamping things to your spoilboard. Do yourself a favor and go read up on how that’s done so you can get a lot of good ideas before it’s your turn to start clamping.

3. Get yourself a misting setup for coolant and use it while being paranoid about chip buildup

If your machine didn’t come with flood coolant, and isn’t set up for it (i.e. you don’t have an enclosure to keep the wet inside), get yourself a misting setup. I got mine off eBay for about $100. It’s a Noga. There are a lot of different brands. Get a jug of coolant to go with it. I use KoolMist, but again, there are a lot of brands.

Now train yourself to be paranoid about chip buildup.

Recutting chips is bad for cutters and in the worst case leads to breakage. Being paranoid means you’re watching the cut like a hawk and you fiddle with your mister’s nozzle until you figure out how to position it right the first time and every time thereafter to blow away the chips from the cut. Learn more about the different CNC Coolant options.

If you’re a CNC Router user, the story is different, unless you plan to cut a lot of aluminum. If you’re cutting aluminum, you still need a misting system. Otherwise, a ShopVac or even just blowing the chips out of the way with compressed air will serve as you cut wood or plastics.

4. Learn how to use MDI

Your next step is to learn to run your CNC as though it was a manual mill with power feeds and DRO’s on every axis. In the process you’ll learn some basic g-codes so that you have some idea what your program is doing the first time you run a real g-code program (that’s a little ways away yet!). It’s very convenient to be able to do this trick, and you can learn all about it through our article on this topic:

[ Every Machinist Must Learn These 9 Simple G-Codes ]

Don’t stop there. When you’ve got a grip on MDI, start on the CNCCookbook G-Code Tutorial.

Start out with the cutter way high and don’t try make any moves in the Z-axis so you won’t crash the cutter into anything. Practice making moves in X and Y. Until the cutter goes where you want it to and you’re not making mistakes.

One more trick: don’t use G00 in MDI–that makes the machine move in rapids mode which is as fast as it can go. Use G01 and set a slow feedrate. “G01 F20” will make the machine move at 20 inches per minute (or metric units if you’re in metric). You’ll have a lot more time to react this way if it starts heading into trouble. Visualize pressing the red E-Stop many times so it’ll be almost automatic when you need it.

5. Get yourself a feeds and speeds calculator and use it

You’re getting close to making your first cuts.

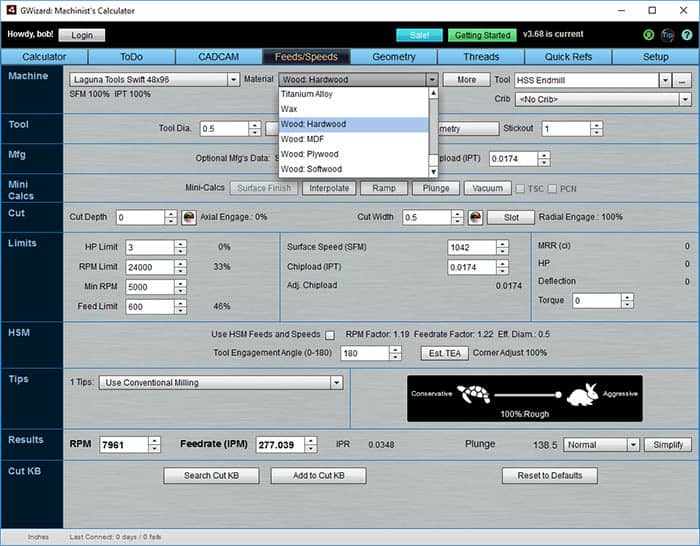

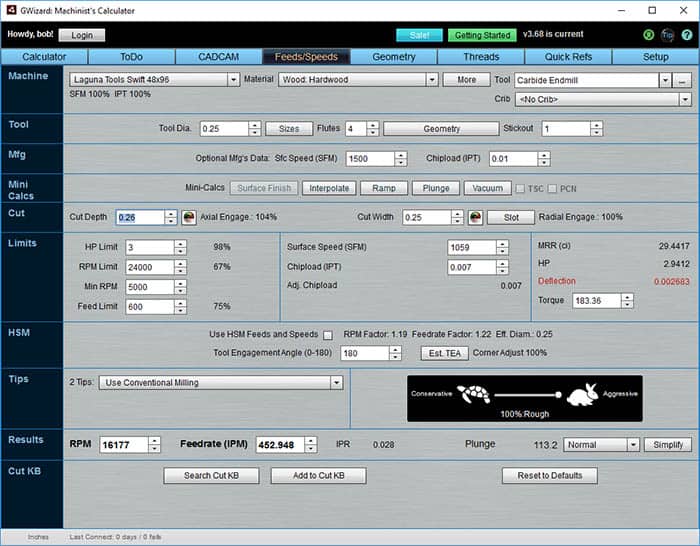

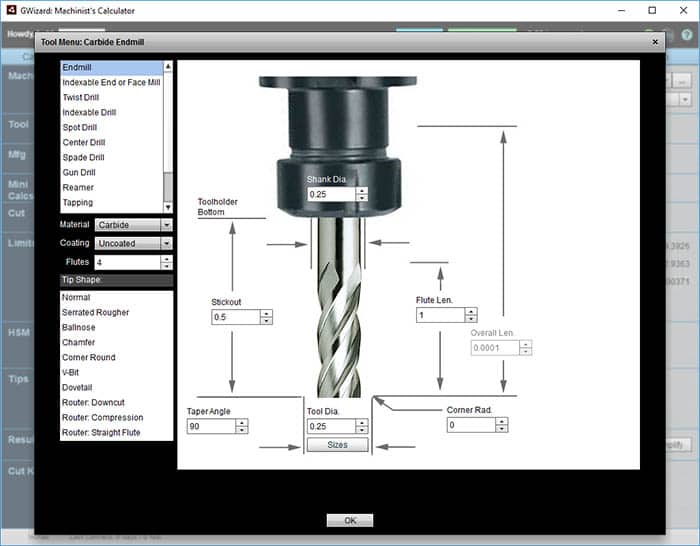

Do yourself a favor and get a feeds and speeds calculator. Trying to figure out feeds and speeds as a beginner or asking people on forums is a recipe for frustration and faillure. And it is such a false economy to try to save a few bucks by skipping the calculator or using a cheezy free online calculator. Stuff will go wrong that you’re just not equipped to understand. So, get a decent feeds and speeds calculator so your spindle speeds and feedrate are perfect for that first cut.

We recommend our own CNCCookbook G-Wizard feeds and speeds calculator (natch!). It doesn’t cost much more than 1 single cutter to get started, and you can use it for 30-days completely free.

Best of all, there’s a great deal just for beginners and hobbyists that we call “G-Wizard Lite”:

When you subscribe for 1 year of G-Wizard, you get Lifetime use of the product for up to 1 horsepower. You can do a lot with 1 HP, especially if you’re a student or hobbyist. In fact, it may be all the power you ever need!

So check it out, your cutters will thank you and your projects will go by faster and easier.

6. Get yourself a Z-height measuring gizmo and learn to use it to touch off your tool lengths. While you’re at it, get an Edge Finder and use it to touch off your Part Zeros.

Your machine needs to know where the tip of the tool is or terrible things can happen.

As a beginner, you tell it by using a Z-height measuring gizmo of some kind. Have a look at our article on the subject to see what’s available. Don’t get wrapped up in the fancier stuff in that article. The first few options will get your going.

Learn how to use these to tell the machine what your tool length is. This process tells your machine where the tip is in Z. To establish the position of X and Y you’ll need and Edge Finder. The first thing you’ll do after sticking a piece of material in your vise and inserting a tool in the spindle is to set these zeros.

You can learn more about touching off and setting part zero from our G-Code Tutorial.

Also take a look at our 2-part series on Tool Data Management for information on Z-Height Gizmos (more properly called touch setters) and tool lengths. Use your newfound MDI skills from #4 to start using your Edge Finder and Z-Height Touch Setter.

7. Learn to Tram your Mill and Vise

How to square and tram your vise on your CNC mill…

Tramming is what machinists call getting things square by sweeping an indicator around. It’s a basic skill everyone needs to learn.

When you first start machining, get into the habit of checking your mill’s tram every time you walk out into the shop. You’ll know later on whether you need to do it every time, but for now, you could use the practice. While you’re at it, be sure you know how to tram your vise so the jaws are aligned properly with one axis or the other. Let’s don’t try to square you mill just yet, but tramming the mill and vise are a good step at this stage.

For details on how to do this, refer to our Mill Tips and Techniques page.

8. Start out with wood, aluminum, brass, and plastic. Avoid stainless.

Okay, the very next step involves making some cuts. Sorry if it seems like you had to do a lot before getting there, but I did say I wanted to tell you some things that will help you succeed and there’s quite a few things in that category!

One more is to avoid difficult materials for your first cuts. Stick with aluminum, brass, or non-metals like plastics and wood.

BTW, nothing wrong with sticking a piece of 2×4 in the machine to learn on, even if the eventual part is going to be made of metal. I often use wood to prototype what I’m doing until I get everything right. It’s a lot cheaper than metal!

When you’re doing okay with softer materials, graduate to mild steel. Only after you feel like you’ve pretty well mastered cuts in these materials can you try tougher materials. Master means you’re not breaking or wearing cutters out too quickly, and your surface finishes no longer look like the material was attacked by a pack of rabies-infected beavers.

One more thing. It’ll be tempting to try some “mystery metal.” This is metal you think you know what is, that you got essentially for free, and that is therefore expendable. Trouble is, a lot of mystery metal is hard to cut. It’s nasty cheap stuff that will break cutters and generally confound you. Not worth it!

9. For your first project, learn how to square a block of material and make yourself a few sets of step jaws in aluminum

Let’s quit procrastinating and make some chips!

For this step, you’re going to start by learning how to square a block of material. Get your saw and cut out some pieces of material that are slightly oversized to serve as vise jaws. Google “Kurt Vise Jaw Dimensions” to find drawings of jaws if you need some. As mentioned, cut the stock slightly oversized from aluminum. Now you need to square those blocks. Squaring means you will make a series of milling cuts until all sides are properly parallel or perpendicular to one another, at which point the workpiece is “square”.

The proper steps for squaring a block of material are described on my Turner’s Cube page. The recipe described there is one I got from the great book, “Machine Shop Trade Secrets.” Pick up a copy to continue your learning process.

One thing about the Turner’s Cube material squaring: I use a Face Mill, but you should start out doing it with multiple passes and a 1/2″ endmill. Why? Because Face Mills generate a lot of force. You can stall the spindle, yank the work out of the vise and throw it across the room, and other shenanigans a beginner could do without.

Leave the face mill in a drawer if you have one already and do it with a 1/2″ endmill the first time until you know a little more what you’re doing. Same goes for fly cutters, and for the CNC Router crowd, those big cutters you use to surface spoilboards. You’re not ready for them yet.

Having squared the material, your next task is to cut it to size by continuing to mill it until it is a perfect fit for your vise jaws (you’ll need 2 square pieces, one for each jaw). The last step is to drill and countersink the mounting holes.

Actually, I wasn’t completely truthful. Once you have mounting holes, the last step is to mill a step along each jaw, maybe 1/8″ square. Now you can use that step instead of parallels when you drop material into the vise. Over time, you’ll learn a lot more tricks with aluminum jaws, but remember: it all started here with your first set.

10. Graduate to CAD/CAM

Friend, you’re now able to do the basics. Sure, there’s a lot more learning to do, but you’re in a position to have a leg up on the manual machinist down the street who has a Bridgeport and no CNC. Your next step is to start pumping out the g-code. To do that, you’ll need to be proficient with CAD/CAM. This is going to be your biggest step yet. Neither CAD nor CAM is very easy to learn.

I give myself 2 weeks to feel comfortable with a new program, and I’ve had the luxury of learning quite a few so far. If this is your first time, get ready to drink from the firehose.

I have put together a bunch of pointers to make it as easy as possible for you to choose the best CAD CAM software for your needs. Check out our Best CADCAM Software for Beginners article. It is chock full of buying guides, evaluation tips, how to learn ideas, and best of all, it has a guide to the secret deals on the most popular packages that can save you money. These are deals most people have no idea exist, including one from CNCCookbook.

Bonus: Delay the need for CAD/CAM a little while with Conversational CNC

Many talented manual machinists run afoul of CADCAM and it stalls their ability to be productive on CNC machines quickly. Even after they’ve learned CADCAM, they’re still left with the feeling that manual machining can make simple parts faster than CNC, because they don’t have to stop to make a CAD drawing and run it through the CAM package to get g-code.

Instead, they can just make a simple bracket with 4 holes shooting from the hip.

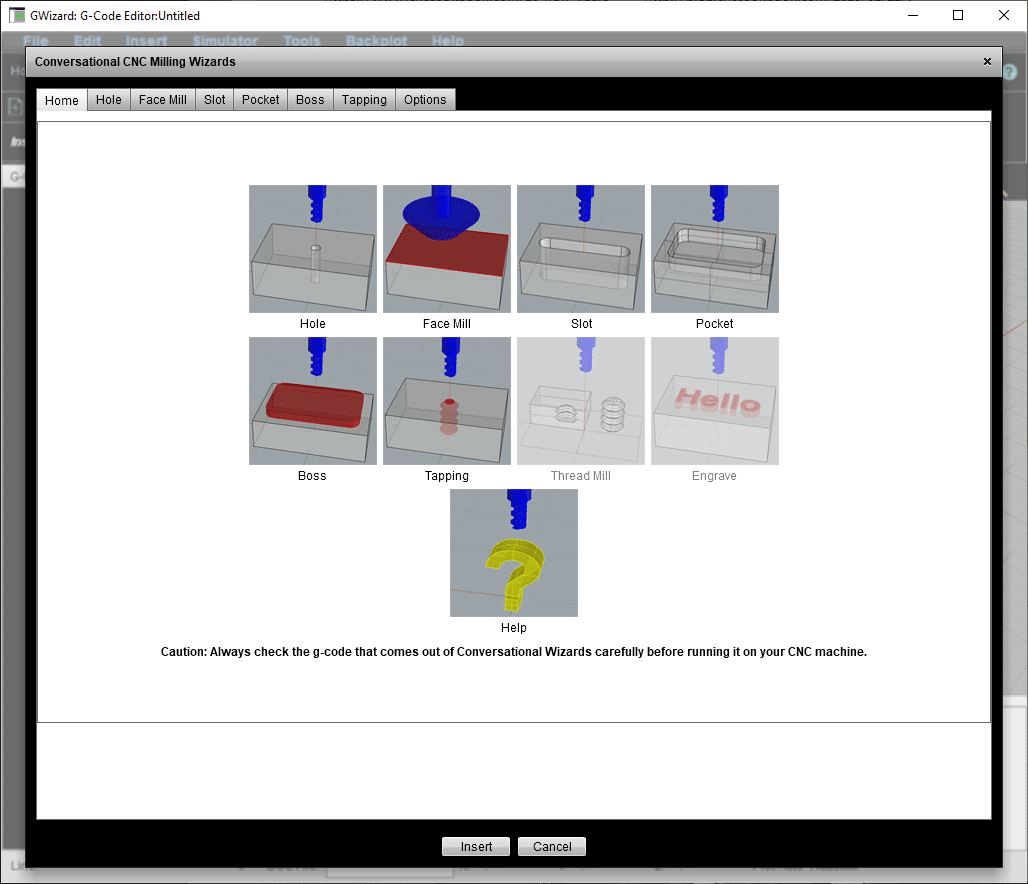

Conversational CNC makes it possible to do that with a CNC machine. Imagine changing the long essay test that is CADCAM to a quick multiple-choice quiz. That’s what Conversational CNC is all about. Here’s the pictorial menu of Conversational CNC operations that can be performed on a mill:

You pick the operation, a popup asks a few simple questions, you press the Insert button, and you’ve got your g-code. We’ve built Conversational CNC right into our G-Wizard Editor product so you won’t have to purchase an expensive stand alone Conversational package.

You’ll still need to learn CADCAM, but with Conversational CNC you can be making simple parts before finishing the CADCAM learning curve.

Congratulations, you’ve got some Basic CNC Skills!

Congratulations, you’ve learned enough to start doing some useful things with a little confidence. If you can design and generate g-code for basic parts with CAD/CAM software, you’re particularly proficient. But stay tuned because there’s a follow up on this article. It’s another installment of things you can do to reach the next level of proficiency. There’s always something more to learn–it’s one of the things that makes CNC so interesting!

Like what you read on CNCCookbook?

Join 100,000+ CNC'ers! Get our latest blog posts delivered straight to your email inbox once a week for free. Plus, we’ll give you access to some great CNC reference materials including:

- Our Big List of over 200 CNC Tips and Techniques

- Our Free GCode Programming Basics Course

- And more!

Just enter your name and email address below:

100% Privacy: We will never Spam you!

Bob is responsible for the development and implementation of the popular G-Wizard CNC Software. Bob is also the founder of CNCCookbook, the largest CNC-related blog on the Internet.

Fantastic list, very helpful! I completely agree with everything on here, especially #4! When I first bought my CNC milling machine taking full advantage of the MDI was probably the hardest part. The work it took to master it wasn’t easy, but definitely worth it! Thanks again for the great post and great blog.

I’ve never owned a set of parallels. I just went right to making aluminum step jaws because it was the obvious thing to do and I didn’t have the money to buy a set of parallels. 😉

The jaws on my vise have a couple of steps at the top plus v grooves along the length and a perpendicular cut across the top I did for a one-off project but its come in handy for other uses.

Once in a while I put the original steel jaws back on the vise.

CNC Mills

Touching off cutters and spot drill.

Best way is_____________________________?

I work at a Technical College. A sheet of paper is used under the tool.

Over travel on Z makes for breakage, I suggested a Z indicator that sets the tool at one inch, and a few key strokes puts the zero where it needs to be. But they insist on paper and breakage as normal. How many shops use paper to touch off tooling? Anyone?

I’ve been meaning to put together a survey on how shops manage tool data. I’ll be sure to include a question about this, Ron.

Get a hardened dowel pin of a known dimension (I use 3/16″). Lower the Z until the cutter is slightly below the dowel pin height, and then raise it until the dowel can be rolled under the cutter. Set the Z axis to the dowel pin dimension.

Height touch off, we use 1-2-3 blocks on bigger machines, 1/2 round endmill shanks or short sections of drill rod for tighter conditions and 1/8 or 1/4 HSS lathe blanks in really tight quarters. You want to verify dimensions with a micrometer before using.

confidence and concept of machining also need

We think you touched on some great points. It’s important to familiarize yourself with multiple aspects of CNC Milling as you get your feet wet. We have also written a blog post on the subject. http://www.cncmasters.com/blog/beginners-guide-to-cnc-milling.html

Thanks for the article, it amazes me that anybody really can get their own cnc machine. I think it is a little complicated though for the regular joe on the street, which is me, but I enjoyed learning about it. I am an entrepreneur though, and I would like to use something like this to produce my next product that I am coming out with.

Bob, it sounds like you have had quite a long experience with working on cnc machining . You know, this is something that my grandson is taking a look at because he is very interested in it. I guess he could take a look at the tips that you provided just so that he can be aware of what to expect.

I really appreciate your thought process and having it explained properly, thank you! I will definitely refer back to this on my next setup.

What cnc milling bit is perfect to cut tempered glass?

You cannot cut tempered glass. Once glass is tempered, the surface is in tension with the core. Any attempt at cutting will result in the entire lie of glass fracturing into tiny pieces.

What cnc milling bit is perfect to cut Marble

I am new at cnc and need step to step settings for starting projects. I am using mach3. I need help for setting z zero and other settings that might influence projects. As well if I use pre setup gcodes.

Thank you

Another great blog, thanks Bob. This is exactly why I recommended my customers check out your website, see https://www.kickstarter.com/projects/2118335444/automate-anything-with-super-gerbil-cnc-gcode-cont/posts/2389234

Good stuff, I prefer to load the indicator and tap the vise away to avoid shocking the indicator from tapping into it. I also save time going to the center of the vise and then to the edge, half the distance, a full length sweep for a final check and tweak if necessary. The technique is each to their own and you covered all the critical steps, good job. Thanks for the videos.

Awesome!