2 months by cncdivi

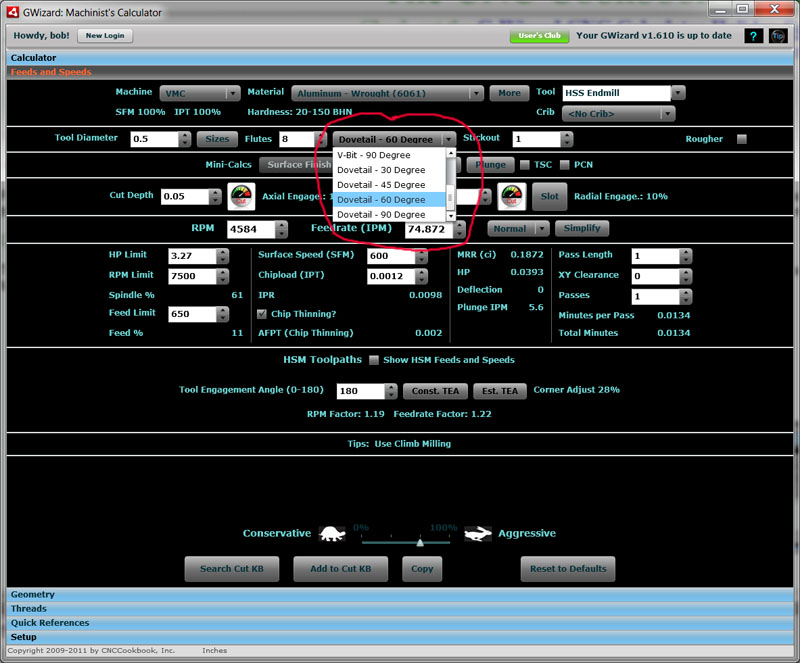

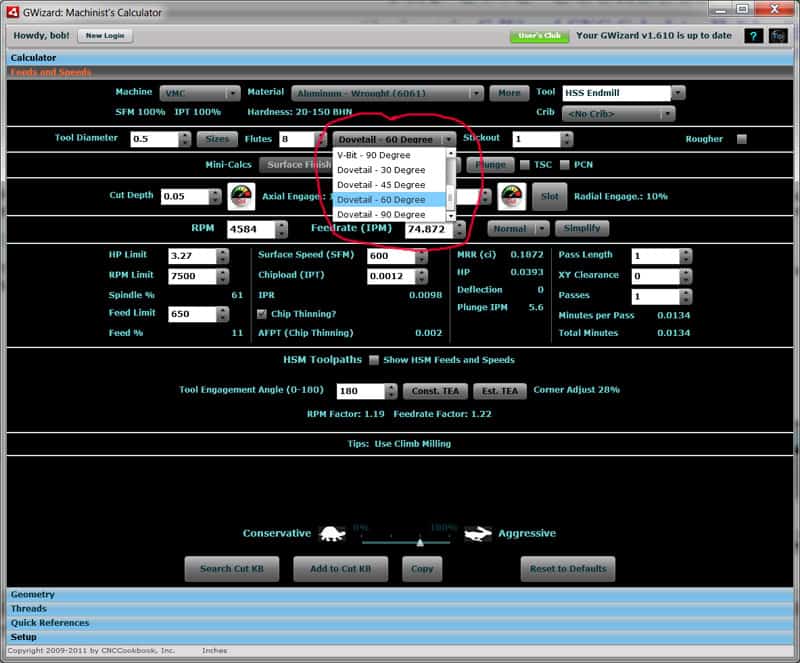

The latest release of G-Wizard, 1.610, has added support for Dovetail Cutters. It’s simply to use, just pick the nearest angle to your dovetail (a lot of angles are available) from the dropdown Geometry Menu:

To calculate feeds and speeds for a Dovetail, use the Geometry menu (circled in red) and select the closest angle to your dovetail’s…

For diameter, be sure to use the diameter of the dovetail, not the shank. You might also consider dialing the “Tortoise/Hare” slide all the way left if you’re not in a great hurry. These cutters are delicate, and that will further minimize the stress on the cutter.

If you’re a registered G-Wizard user, the install page for version 1.610 is here. If you haven’t tried G-Wizard, sign up for the free 30-day trial, plus there’s a Holiday Sale underway that has some of the best deals we’ve ever offered.

More Tips When Cutting Dovetails

I came across a great thread on PM while researching Dovetail Cutter Feeds and Speeds. Some tips:

– Be sure to open a slot as wide as you can with a regular endmill that is also slightly deeper than the dovetail. You want to minimize the work your dovetail cutter has to do and they’re not really designed to do the full slot.

– Having opened up the slot, you still want to baby the cutter through–don’t expect to cut both sides in one pass at full depth.

– You can make partial passes running the cutter along the top and both lowering it and moving it laterally into the cut each pass, the way you would move the cutter along the thread “wall” when cutting threads. For each pass, go down say 10-15% and then feed laterally until you get to the edge. This is a typical step down you’d perform pocketing, it’s just you’re doing it with a dovetail and typically in a straight line.

– If you need the clearance, use a smaller dovetail cutter of the same angle so you can make those step passes and then move to a full-sized cutter for final finish.

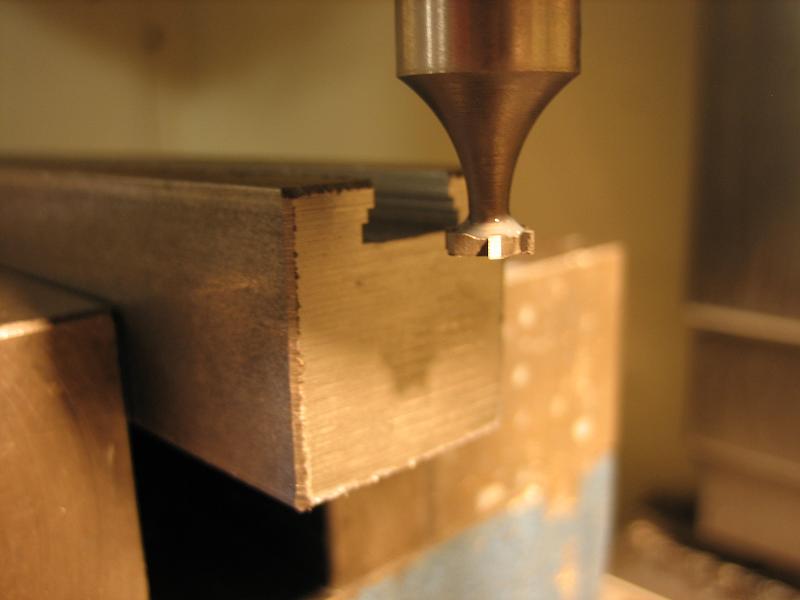

– You can use a different and less delicate cutter to step profile and then clean it up with your dovetail in one or more passes:

Step profiling the dovetail with a T-Slot cutter

Like what you read on CNCCookbook?

Join 100,000+ CNC'ers! Get our latest blog posts delivered straight to your email inbox once a week for free. Plus, we’ll give you access to some great CNC reference materials including:

- Our Big List of over 200 CNC Tips and Techniques

- Our Free GCode Programming Basics Course

- And more!

Just enter your name and email address below:

100% Privacy: We will never Spam you!

Bob is responsible for the development and implementation of the popular G-Wizard CNC Software. Bob is also the founder of CNCCookbook, the largest CNC-related blog on the Internet.

![Fly Cutter: Ultimate Surface Finish Rewards [Complete Guide] A detailed drawing of a machine with a fly cutter attachment.](https://www.cnccookbook.com/wp-content/uploads/2017/09/WidgitFlyCutter.gif)

![Spoilboard Cutter Review [8 Popular Router Bits] A close up of a spoilboard cutter.](https://www.cnccookbook.com/wp-content/uploads/2020/06/img_5eeb9bb4b0cb7.png)