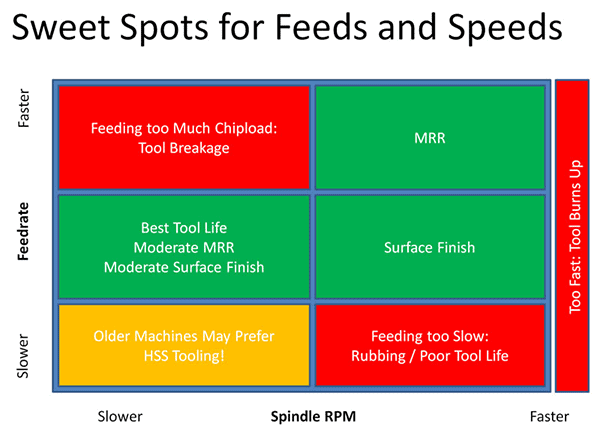

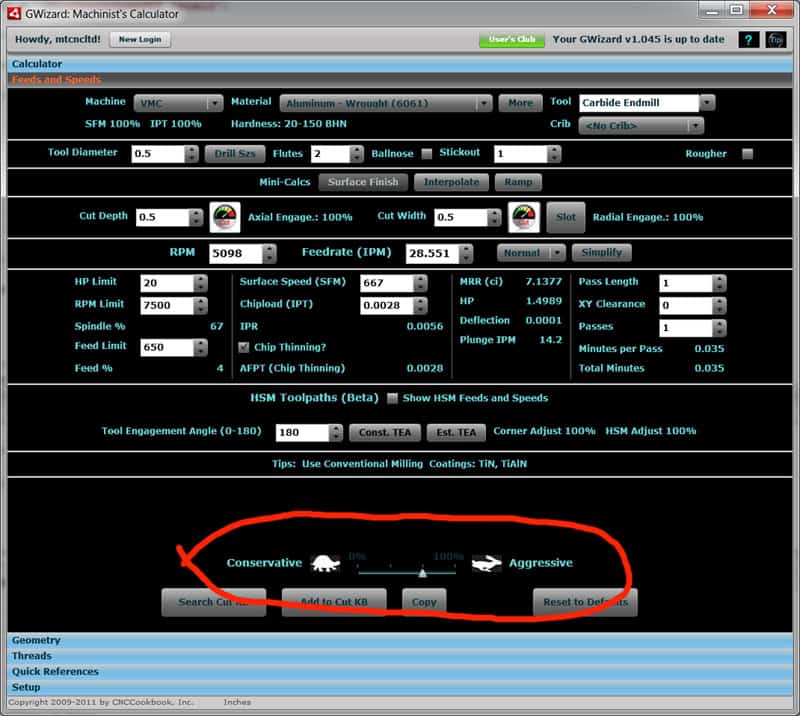

Get Better Feeds and Speeds.

Instantly.

If you’d like to become a Better CNC’er, you’re in the right place.

If you’d like to become a Better CNC’er, you’re in the right place.

We produce world-class CNC Software, and we give away tons of CNC-related information to help.

Hi, my name is Bob Warfield, and I founded CNCCookbook over 10 years ago.

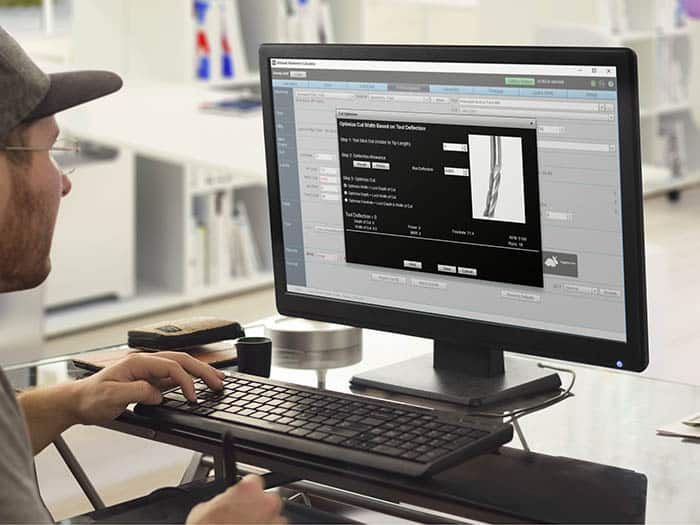

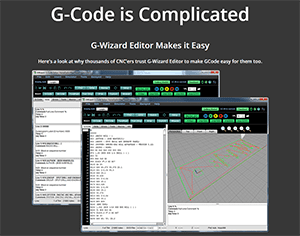

The first thing I noticed looking at software for machinists was that it didn’t follow the best practices of the broader software markets, and it didn’t seem to recognize the needs of the machinist in many fundamental ways.

Being a machinist is a tough business. Margins are thin and competition is intense. Whether you’re a Pro or Hobbyist, CNC is complicated. Mastering all the skills is never easy and is something you’re never done with.

So much software is so focused on giving you more options that they forget to help you choose the best options. Not CNCCookbook–that’s our special niche.

CNCCookbook was created to help everyone become a better CNC’er, no matter what skill level you’ve reached. Only great customers can help us create really great software, and we depend on you for everything.

Our customers are our only investors, and we pay back that investment in every way we can. We run the kind of business we’d like to be able to do business with, and we hope you will do business with us too.

Best,

CUSTOMER REVIEWS

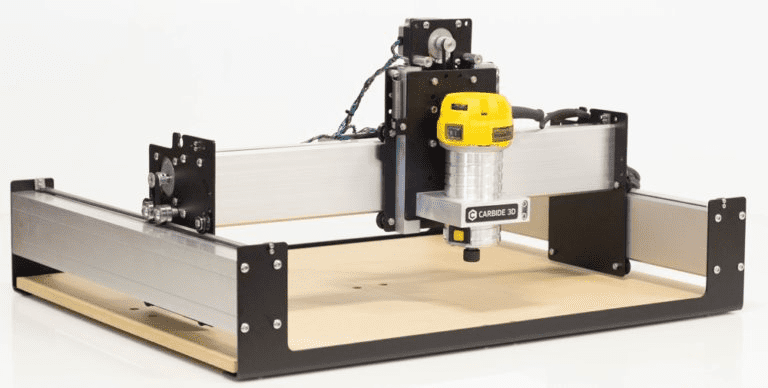

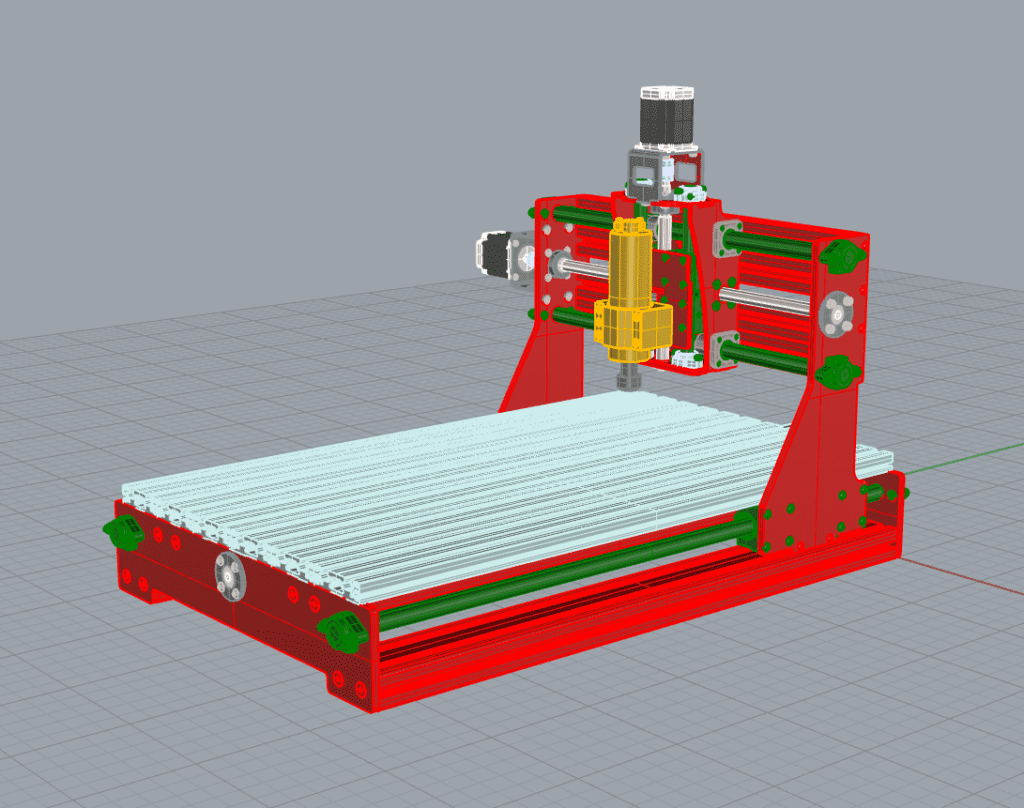

DIY CNC Complete Guide

Complete CNC Router Parts [DIY Guide]

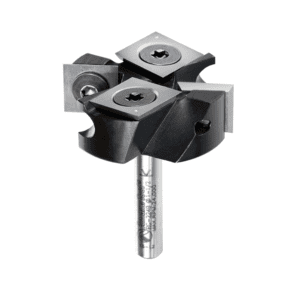

CNC Router Feeds and Speeds Calculator

Recently updated on April 25th, 2024 at 10:00 am